Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Jan 9, 2011 21:38:54 GMT

All exposed mains terminations should be insulated by the use of heatshrink tubing, or better still, the use of a rubber shroud similar to that shown at the attached link.Alex www.jaycar.com.au/productView.asp?ID=PM4016&keywords=PM+4016&form=KEYWORDJoe If you feel the unit is not safe in it's present state, then fix the bloody thing ! You don't always get more chances when playing with 230/240 mains.

|

|

joethearachnid

Been here a while!  Old head on young shoulders.

Old head on young shoulders.

Posts: 380

|

Post by joethearachnid on Jan 9, 2011 22:12:44 GMT

Alex - don't worry, it's all safe now.

I suddenly remembered that I had a few 1Mohm resistors around from a previous project, so I paralelled two of those and so now have 500k between the chassis and ground. That eliminates any mains noise I was getting. All mains connections have been insulated twice in most cases.

Hmm. I'm loving the amp but I'm seriously considering busting it all out of the case again and fitting some 300Rs to up the gain a bit. I'm currently averaging about 12-2 o'clock, which would be fine but with cans this sensitive makes me question how much headroom I'm getting. I'll resist (geddit?) for now.

Thanks again, Frans.

-JoetheArachnid

|

|

|

|

Post by gumleguf on Jan 10, 2011 13:03:29 GMT

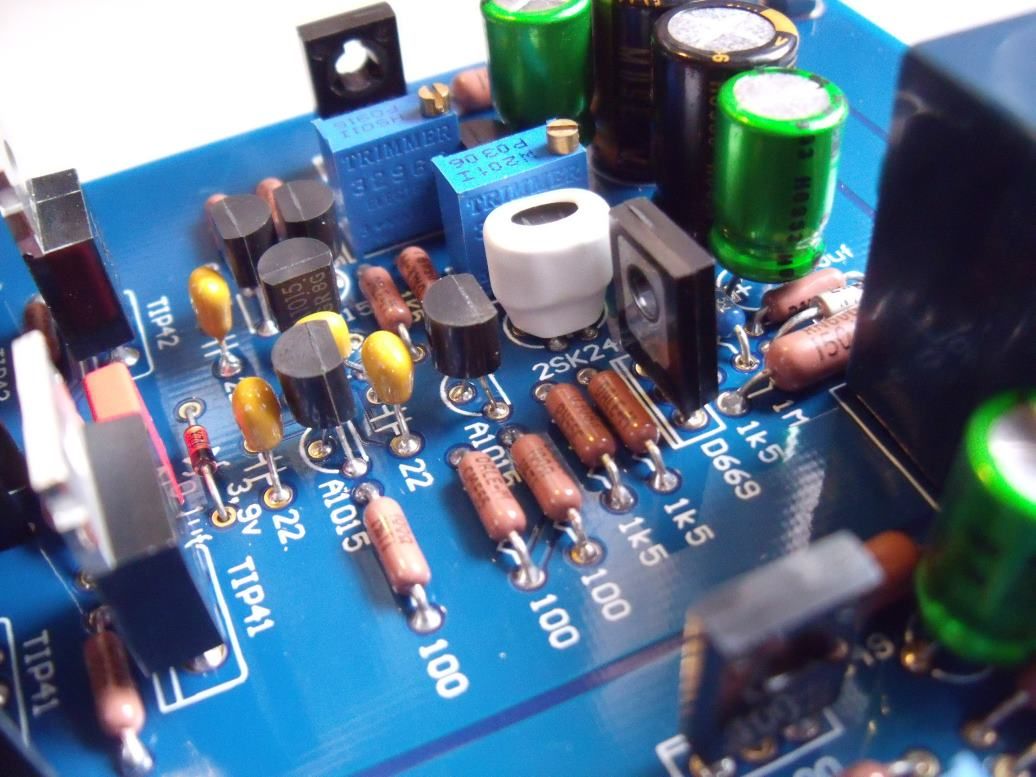

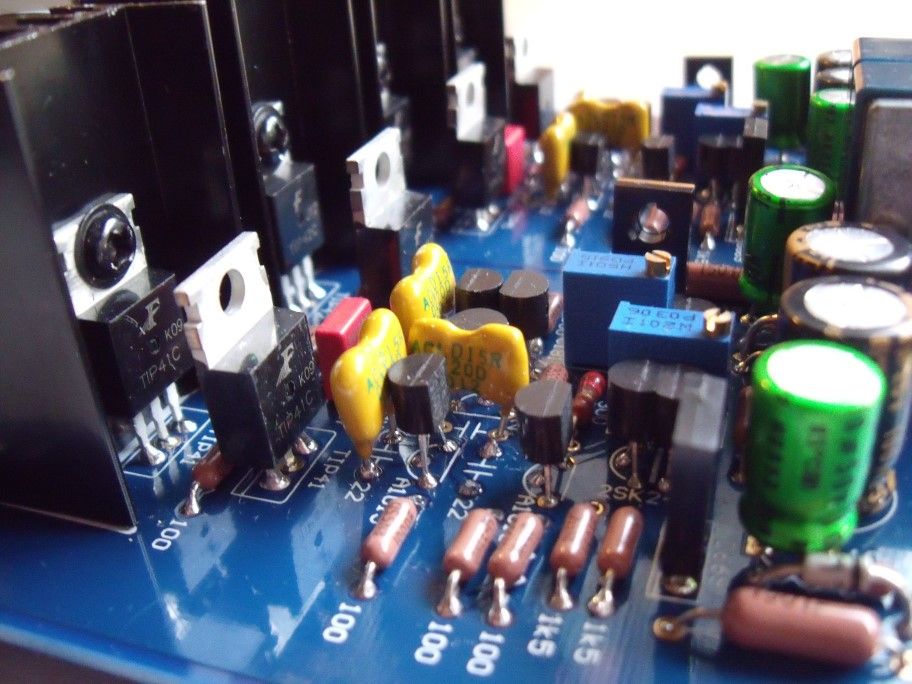

Here's a link to a (crazy) danish guy showing in details and with pictures how to populate the PCB: www.mcfrede.dk/panda_headamp.shtmlAny comments on how heatshrink is used over the transistor pairs? |

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Jan 10, 2011 13:13:30 GMT

simply slide the stuff over (it must be slightly bigger in diameter then the 2 fets together), then heat it.

You can use a cigaret ligther but it tends to scorch the stuff.

a paintremover heatgun can be used from an appropriate distance or a blow dryer.

Maybe also a small tie-wrap* can be used instead of heatshrink tubing.

Another option would be to glue them together.

take the thickness of a tie-wrap*under consideration as it is right next to a pot.

* (you know what I mean)

|

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Jan 10, 2011 18:22:25 GMT

Here's a link to a (crazy) danish guy showing in details and with pictures how to populate the PCB: www.mcfrede.dk/panda_headamp.shtmlAny comments on how heatshrink is used over the transistor pairs? Uhm, I guess I am that (crazy) dude... ;-) Regarding the heatshrink I found some that were just the right size, bigger will be harder as it will slide down, mine was a snug fit... If all I had was some heatshrink that was too big I guess I would pre-shrink it in the top to fix it when sliding it down over the transistors. I use a cigarette lighter, it is perfectly doable without scorching the heatsrhink. I heat with the blue part of the flame, not the orange part as that will most likely cause visible burns on the heatshrink. Glad someone stumbles across my webpage. |

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Jan 10, 2011 19:23:44 GMT

I believe heatshrink is recommended both in this thread and the original Panda thread. It keeps both jfets pressed together in the first place, which makes sure they are at the same temperature. If they would be at different temperatures, the DC offset on the output can drift under changing thermal conditions. I concur! When I measured the transistors, even handling them with my fingers made a difference on my readings. I guess the idea of matching the transistors really makes the most sense if you couple them thermally also. Then again I do not know if the coupled transistors thermal performance scale equally, but you have to stop at some point. |

|

|

|

Post by PinkFloyd on Jan 10, 2011 19:31:15 GMT

. I believe heatshrink is recommended both in this thread and the original Panda thread. It keeps both jfets pressed together in the first place, which makes sure they are at the same temperature. If they would be at different temperatures, the DC offset on the output can drift under changing thermal conditions. The transistors are thermally coupled so they should be touching, this ensures they are both running at the same temperature. Best way to do it is to fit the transistors into position but do not solder them.... fit a bit of heatshrink over them and then heat the heatshrink... as it contracts it will force both mating surfaces of the transistors together, then solder them into position. If you solder "first" then there may not be enough "play" to allow the surfaces to butt together. You can then apply a second piece of heatshrink and if you want to get really anal you can fit a bleed nipple cover (the rubber ones on brake bleed nipples) this should keep them nice and warm  First mentioned in post #69 of the original thread: By the way... the "kissing pair" of transistors I mentioned... wrap them in a white coat to keep them warm   |

|

|

|

Post by PinkFloyd on Jan 10, 2011 19:47:15 GMT

Welcome to the forum man  Nice webpage, it should make things a bit easier for people, if you have any questions or need a hand just let me know. All the best, Mike. Thanks, I might hold you to it! All I really did was read up on your thread, assemble my own Panda and take some more photos. Kudos to you! What do you think of the sound quality? I am on Panda MK4 at the moment and it's amazing how you can "tune" the sound just by using different caps, bypassing caps etc. The only downside with these boards is they are not too user friendly when it comes to rolling parts in and out.... through hole can be a bitch, especially with small parts.... so I have made four different models (soon to be five) and will compare them all and "eventually" do a write up. All I can say, at this stage, is that the stock kit is VERY good but certain aspects of the sound can be tuned up "to taste" without too much effort  |

|

|

|

Post by PinkFloyd on Jan 10, 2011 20:15:59 GMT

|

|

|

|

Post by PinkFloyd on Jan 10, 2011 20:30:43 GMT

Panda three was a bit more "crazy tune" bypassing   With silvered mica instead of the ceramics....  It's finding the time Dicky.... not so much the "building" but the time to listen in-depth to everything. At the moment, I have a NECO dual mono in and am building a power supply for it, I have 15 Little Pinkies to make, I've got Jari's V3 here, a couple of V-CANS to mod, two V'3s to mod, a V2.... it goes on and on.... I'm not complaining BUT I just don't know where the time goes these days... I just cannot do what I used to be able to do, I would LOVE to spend an entire day doing a write up on the Panda but "physically" just can't be in two places at one time  |

|

joethearachnid

Been here a while!  Old head on young shoulders.

Old head on young shoulders.

Posts: 380

|

Post by joethearachnid on Jan 10, 2011 21:49:13 GMT

Just upped the gain - paralleled some 330Rs across the 300Rs. Comfortable listening is now 10-12 o'clock, which is better in my opinion. I get to make use of the first half of the pot's motion and I also have plenty of headroom left for any harder-to-drive higher-end cans I may pick up later. I'm not sure that I'll ever need to buy another high-end solid state amp, though.  As I've mentioned before, I get some very slight noise on full volume, but I think this is mainly due to my low-impedance/high sensitivity cans. I was doing some vague noise tests and couldn't understand what I'd done to make the amp so utterly quiet all of a sudden. I then realised that not only was the amp not switched on, it wasn't even plugged in. I think I'm getting old and I'm not even 18 yet... Anyway, I'm fairly sure right now that most of my noise is coming from my sources, with only a fantastically low hum at full volume... which I could NEVER reach with the upped gain without serious ear damage, so I think I'm safe. I'm now resolving not to crack open the case again. Except maybe a few DC offset adjustments. Or if Mike find a REALLY good mod... Maybe I should get hold of a bit of pyrite? -JoetheArachnid |

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Jan 11, 2011 6:03:28 GMT

Solid State mains powered headphone amplifiers should be silent at maximum volume with proper design and construction techniques.

Excessive gain can contribute to a little hiss or hum.

|

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Jan 11, 2011 9:07:23 GMT

I also get some hum when there is no music and the amp is loud. I have yet to hear an amp for mains that is silent.. That might also be caused by your wooden enclosure that provides no screening.  Beautiful as it may be  You often cannot do much about hiss without changing certain parts. Hum, usually, can be eliminated.  |

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Jan 11, 2011 9:15:56 GMT

here is something I wrote previously and is applicable in this sitution perhaps:

Every transformer and SMPS has a certain leakage from the mains (primary) to the secondary.

This all depends on the type of transformer/SMPS.

The higher the frequency the worse it gets.

This is due CAPACATIVE coupling between the windings or windings-core-windings.

It all depends if the live wire (which has a voltage on it referenced to ground) is closest to the secondary windings or the neutral is closest.

That is where the biggest leaking comes from.

In case of SMPS the leakage is caused by capacitors used to comply to rules or capacitance through the transformer.

2 ways of detection:

1: use a voltmeter in 300V AC voltage mode. connect one lead to a safety ground or your waterpiping or central heating and the other one on a metalic part or ground of an RCA plug with the device under test ONLY connected to the mains and NOT the other equipment.

Find the position of the plug that shows the lowest voltage. mark it (with respect to the wall socket you test on) the device must be 'on' ofcourse.

2: method without a meter: plug the device in and switch on (not connected to anything else).

Rub your finger over the metalic front (if present) or metalic housing.

If it feels like your finger hums... or bounces slightly (a strange sensation in the tip of your finger) then turn around the mains plug and try again. Mark the position for lowest 'event'.

Now what is this excercise good for ?

The idea is that when you have done this for all gear involved the lowest amounts of leakage currents of all the separate gear will be going through the SCREENS of the interlinks (and not through the centre wire otherwise you would hear that).

The lower this current the better the sound quality some claim.

Like you I cannot hear it but many claim they can and the differences are HUGE (as always)

Why is it a wise thing to do this anyway ?

If you ever had the problem in your audiosystem that you hear low level hums 'ticks' and certain sounds that eminate from washing machines, lamps being switched on/off e.t.c. chances are these have become audible because of these too high currents inbetween devices in the audio system.

Seeking the lowest leakage current helps in this case and possibly eliminates most problems.

You can also connect all of the metal parts from these devices together and connect this to a safety ground... helps too but sometimes makes things worse.

Things with a switch mode power supply (which most things have nowadays) are even worse and often do not have a leakage current as low as when regular transformers are used.

It may be always the same regardless of mains plug orientation.

a PC connected to an UNGROUNDED wall socket is by far the worst you can get and TV's also as these usually don't have grounded mains connectors.

|

|

|

|

Post by clausdk on Jan 11, 2011 9:41:36 GMT

I also get some hum when there is no music and the amp is loud. I have yet to hear an amp for mains that is silent.. That might also be caused by your wooden enclosure that provides no screening.  Beautiful as it may be  You often cannot do much about hiss without changing certain parts. Hum, usually, can be eliminated.  I have metal bottom in the box so there is metal for ground. The hum is in every map I ever owned about 15 or so, the ones for batteries does not hum.. But remember we are talking volumes wayover what is normal levels.. |

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Jan 11, 2011 10:11:12 GMT

Just having a piece of metal in a box is not sufficient (as with antenna's)

It needs to surround the whole amp and wiring and connected properly on one or multiple points with the PCB.

This is dependent on PCB layout and casing type.

None of my amps have audible hum (working on mains or battery operated) and amps don't have to.

Unless we are talking about mechanical hum eminiating from the enclosure caused by the transformer and not about electrical hum audible in the headphones.

Some transformers can be clearly heard in a quiet room in the evening.

Hum is mostly a ground problem or bad amp/powersupply design or wiring/grounding not done correctly.

|

|

joethearachnid

Been here a while!  Old head on young shoulders.

Old head on young shoulders.

Posts: 380

|

Post by joethearachnid on Jan 15, 2011 15:05:55 GMT

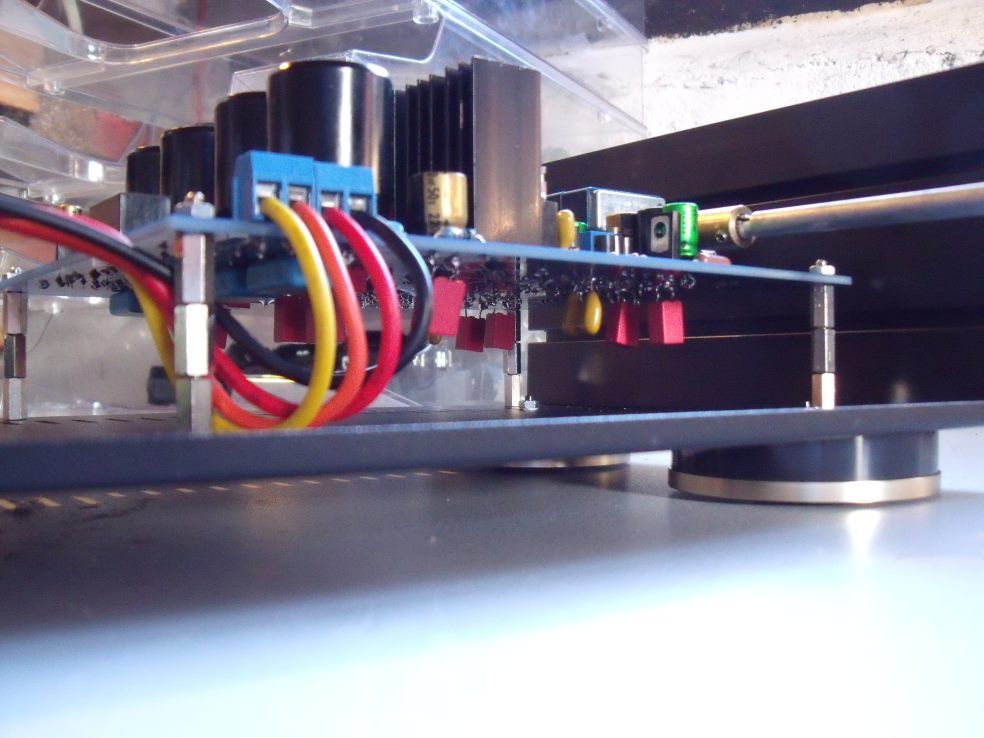

Okay, the caps from Mike arrived (thanks again Mike) and I've fitted the 470nf across L and N. No difference, as far as I can tell.  I already have a varistor fitted and I haven't installed the caps between L and N and ground because I've got 500kohms between the chassis and mains ground and I get the feeling that in that case the path of least resistance is probably through me. Perhaps someone else can enlighten me here. After that I sighed and removed the PCB from the chassis and spent about an hour going over any even vaguely suspect-looking joints. Having done that, I readjusted the volatge across the 1k5 resistors and the DC offset, plugged it back in... and the hum is still there, loud and clear from about 3 o'clock onwards. With nothing plugged in the back (except power, obviously) it's utterly silent, but with any source (DAC, iPod, CDP) I always get the same kind of hum, so I assume that it's a problem with the amp still. I think I'll just leave it be for a while.  -JoetheArachnid. |

|

|

|

Post by gumleguf on Jan 15, 2011 18:49:45 GMT

Just having a piece of metal in a box is not sufficient (as with antenna's) It needs to surround the whole amp and wiring and connected properly on one or multiple points with the PCB. This is dependent on PCB layout and casing type. None of my amps have audible hum (working on mains or battery operated) and amps don't have to. Unless we are talking about mechanical hum eminiating from the enclosure caused by the transformer and not about electrical hum audible in the headphones. Some transformers can be clearly heard in a quiet room in the evening. Hum is mostly a ground problem or bad amp/powersupply design or wiring/grounding not done correctly. Have some newb questions about the above. Hope it's ok. I have plans for an all wooden enclosure, but I guess the best thing then would be to cover all the insides with aluminum (basically build an aluminum box and then "cover" it with wood). Does the thickness of the aluminum have anything to say? Or could I cover the inside of the wooden enclosure with a copper foil shielding or could I paint the insides with a conductive paint instead? |

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Jan 15, 2011 19:06:35 GMT

It needs to be conducting metal AND it has to be connected to a ground connection of the PCB (one PCB hole seems to be connected to ground).

thickness is not very relevant, you just need top create a 'faraday cage' as good as possible.

It has to be surrounding the whole device.

Foil (aluminium foil or tape) or even copper mesh (fine holes) will do too as long as it makes contact all around and is grounded which you can put inside a non-metal enclosure, you can use any material you want for this.

Take precautions the metal housing MUST be kept away from mains voltages.

Personally I wouldn't use conducting paint.

|

|

|

|

Post by PinkFloyd on Jan 15, 2011 23:07:28 GMT

Do a Google for "slug barrier copper tape".... top quality stuff and you can solder onto it..... it's self adhesive and 4 metres should be enough to coat your enclosure with  I would prepare the panels of the enclosure with copper tape "before" joining together.... the slug barrier tape is CHEAP and far superior to any "boutique" tapes I have tried. Just make sure you solder a wire from the PCB ground onto the copper tape  This is only an example.... you will find it cheaper  www.crocus.co.uk/product/_/tools/pest-control/slug-barrier-adhesive-copper-tape/classid.2000008352/ www.crocus.co.uk/product/_/tools/pest-control/slug-barrier-adhesive-copper-tape/classid.2000008352/ |

|

|

|

Post by PinkFloyd on Jan 15, 2011 23:10:40 GMT

|

|

|

|

Post by PinkFloyd on Jan 15, 2011 23:14:49 GMT

|

|

|

|

Post by gumleguf on Jan 16, 2011 10:36:45 GMT

solderdude, PinkFloyd > Thanks both for explanations and suggestions.  I think I'll go for copper tape. Additional question: Simply overlapping the copper tape while covering the insides probably doesn't ensure that all pieces are electrically connected, so should I solder all the pieces together? Is this necessary in order to create a decent working Faraday cage? |

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Jan 16, 2011 11:04:49 GMT

Theoretically (in practice also) it is optimal to solder the whole edges where the tapes meet. You can create a perfect faraday cage which of coarse will be broken for RF where the powerinlet is, unless you use a filtered AC mains socket with a metalic mounting surface and connect this everywhere to the coppertape surrounding it.  But then again the cage will be broken when a HP is connected and when connected to source equipment.  Ah wel...l it will be a very good housing..  |

|

|

|

Post by gumleguf on Jan 16, 2011 11:31:15 GMT

Theoretically (in practice also) it is optimal to solder the whole edges where the tapes meet. Interesting. I found a picture of that. It might take some time, but if it's worth it I'll do it:  You can create a perfect faraday cage which of coarse will be broken for RF where the powerinlet is, unless you use a filtered AC mains socket with a metalic mounting surface and connect this everywhere to the coppertape surrounding it.  But then again the cage will be broken when a HP is connected and when connected to source equipment.  Have ordered a Schurter 4304.4064, the one that is on phase-out: www.schurterinc.com/var/schurter/storage/ilcatalogue/files/document/datasheet/en/pdf/typ_FKI.pdf. Ah wel...l it will be a very good housing..  Sure hope so.  |

|