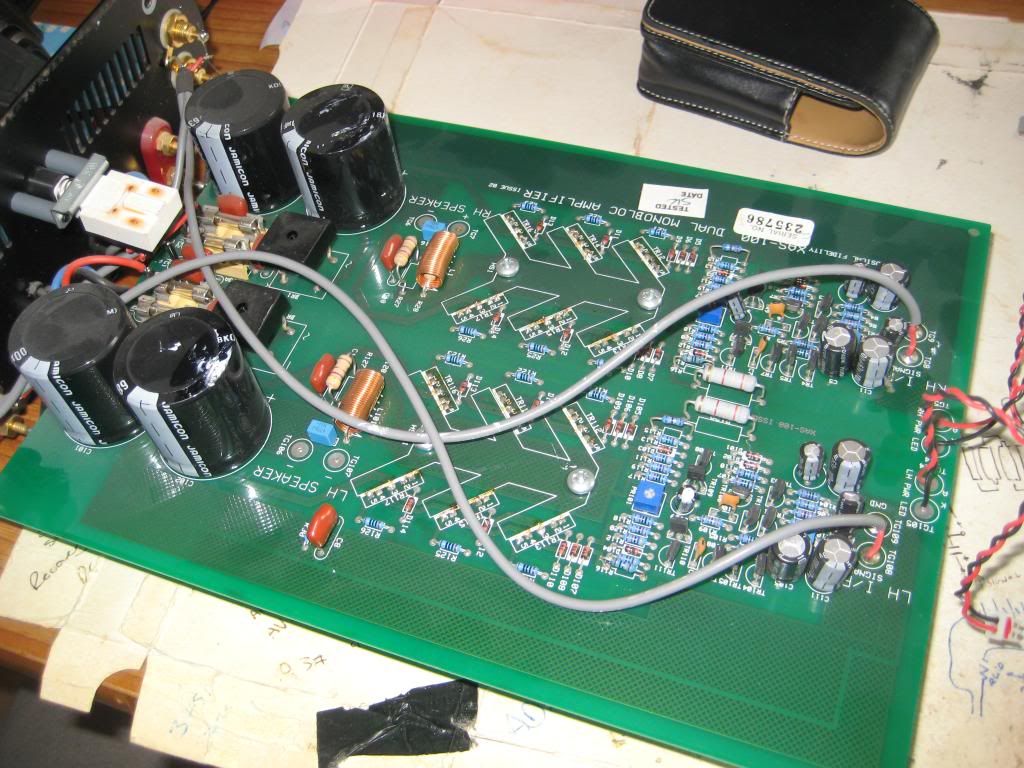

X-AS100 upgrade

Jun 1, 2013 14:13:17 GMT

Post by eightdigitword on Jun 1, 2013 14:13:17 GMT

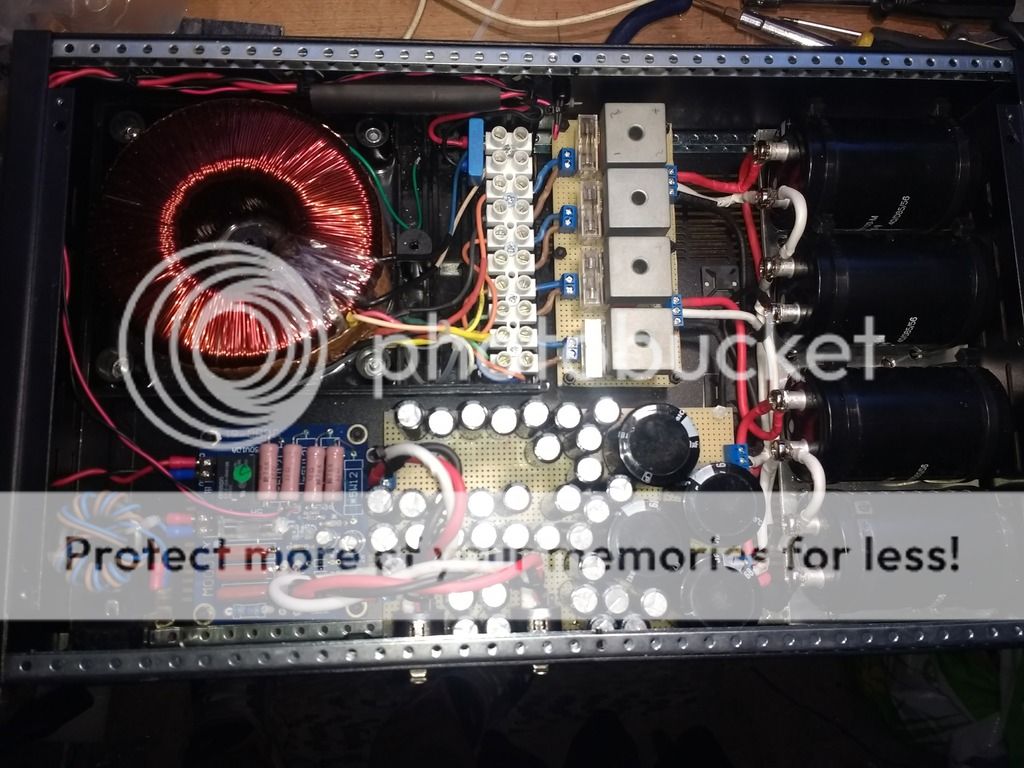

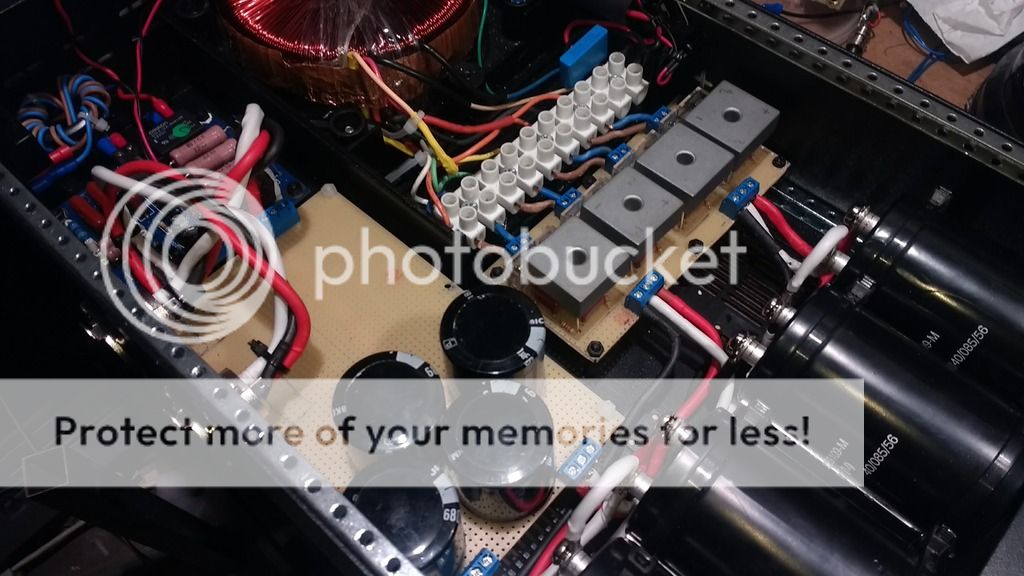

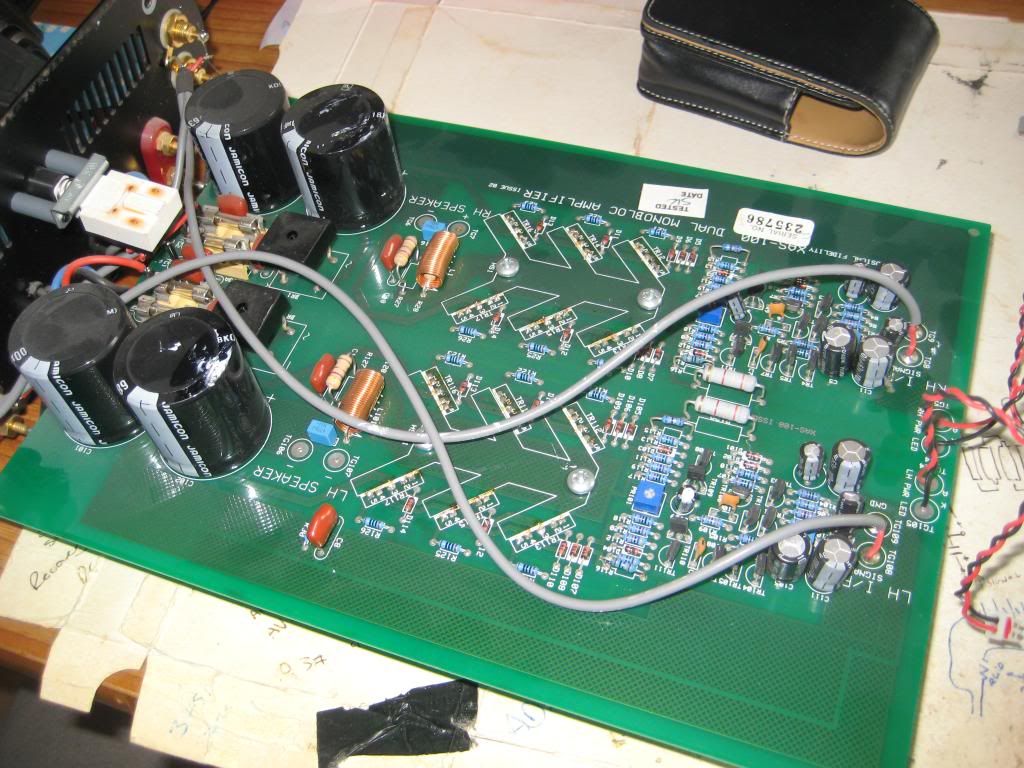

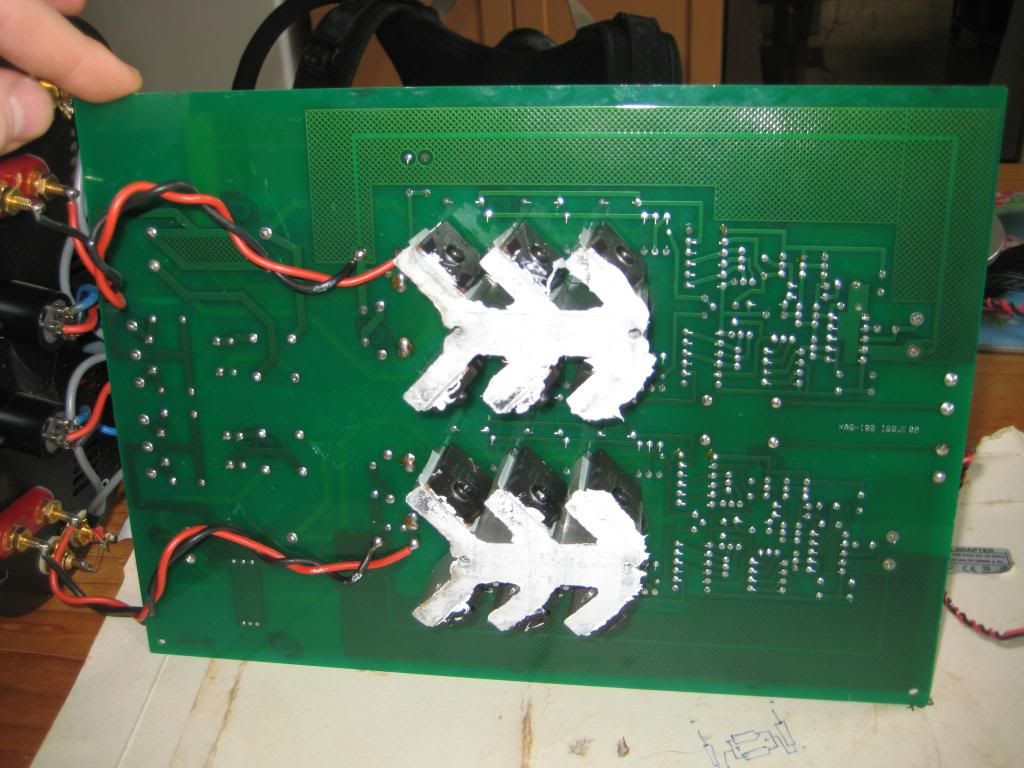

Currently upgrading both my power amps, thought i'd share the pics, progress and findings.

X-AS100 (x2) Power Amp upgrade plans:

Copper bus bar fitted to phono input/output shared signal L&R

Transformer output is 40v AC + 80v AC to amp, bigger transformer (1KVA 240 x2 40)?

0.22uf MKT 'X2' cap used at mains input on PSU

Re-wire PSU cable to amp cable, thicker cable, twisted pair

Bypass PSU electrolytics with polypropylene type: 0.01uf Vishay MKP1837, LH: C101, C102, RH: C1, C2

Check PSU caps ESR, replace if needed, = 0.03-0.06 ESR from stock PSU caps, surprising from big Jobbycons

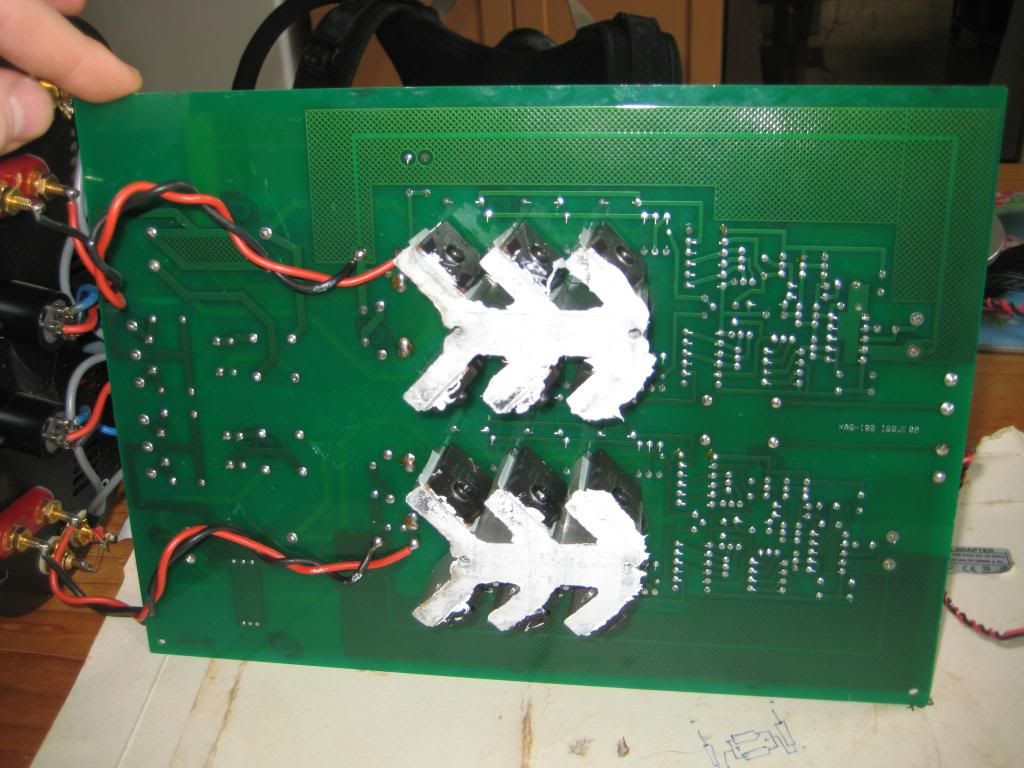

PSU electrolytics x4, 6800uf 63v. LH: C101, C102, RH: C1, C2. board can take 50mm dia x 55 tall: Nichicon KG Gold Tune TYPE I 10000uf 63v audio will fit nicely. 31mm height available underside of PCB for more caps if need be, same 50mm dia limit.

MF recommend to bypass (shunt) all audio path electrolytics with high grade polypropylene. Good idea?? - I'm not sure

C3: 10uf 50v NP -ELNA NP

C103: 10uf 50v NP -above

C5: 100uf 16v NP -Nichicon ES type

C105: 100uf 16v NP -above

C9: 1uf 63v - Audio cap, panasonic EB or possible PP film still to check DC on board at this location

C109: 1uf 63v -above

C10: 100uf 63v -Fitted ELNA SILMAC II 63v, going to test with Nichicon KZ also - input de-coupling, signal to earth

C110: 100uf 63v above

C11: 100uf 63v -above

C111: 100uf 63v -above

C19: 220uf 10v -ELNA Cerafine

C119: 220uf 10v -above

Replace BR with Schottky diodes RS: 395-2487 or fast recovery diodes RS: 688-2293 (15ns recovery)

Clean board with isopropenol

Replace polyester PSU and supply 'bypass?' caps with high grade polystyrene or polypropylene in large capacitance (wima)

C8 - 104J 250v - Replace with 0.1uf 100v Wima

C20, C21, C22 : 104J 250v - Replace with 0.1uf 100v AC Wima

C120, C121, C122 :104J 250v - Replace with 0.1uf 100v AC Wima

Replace polyester plastic film caps at output with polystyrene K71-4: C18: 0.22uf, C118: 0.22uf

Pure copper noise nulling 'belly band' screen fitted to mains transformer, copper tape. soldered and earthed

Replace internal hookup cables with twist pair. 0.7 mm fine silver (99.99% pure) with teflon screen

Twist mains wires and fit a screen using foil tape and heat shrink

Refurbish sockets, check for wear, replace anyway!

Replace ceramic with polystyrenes

C7: 47pf - NOS 47pf 63V POLYSTYRENE FILM & FOIL CAPACITORS - STYROFLEX CAPACITOR KS - heat sink when fitting

C107: 47pf - NOS 47pf 63V POLYSTYRENE FILM & FOIL CAPACITORS - STYROFLEX CAPACITOR KS - heat sink when fitting

Hot glue fix polystyrenes to reduce vibration

Adjust bias to each side

X4 Fuses: F6.3A L 250v removed & polished

slowly working my way through the list, changing bit by bit and listening for a day or so, longer if burn in time is needed. so far sound is improved (i wont go into BS). Surprising improvement came from the copper band fitted round my toroidal transformers in each of my PSU enclosures. I've got 6 sat about a meter away from my hi-fi, i fitted them all with (20mm) copper bands at the same time and was surprised to hear more bass come through than before. This was cheap so i gave it a bash, nothing to loose, probably wouldn't have believe someone if they had told me, bit 'snake oily'. The band must go completely around the toroid and be soldered to to itself, I ran i cable from it (soldered) to the earth pin on my IEC socket.

X-AS100 (x2) Power Amp upgrade plans:

Copper bus bar fitted to phono input/output shared signal L&R

Transformer output is 40v AC + 80v AC to amp, bigger transformer (1KVA 240 x2 40)?

0.22uf MKT 'X2' cap used at mains input on PSU

Re-wire PSU cable to amp cable, thicker cable, twisted pair

Bypass PSU electrolytics with polypropylene type: 0.01uf Vishay MKP1837, LH: C101, C102, RH: C1, C2

Check PSU caps ESR, replace if needed, = 0.03-0.06 ESR from stock PSU caps, surprising from big Jobbycons

PSU electrolytics x4, 6800uf 63v. LH: C101, C102, RH: C1, C2. board can take 50mm dia x 55 tall: Nichicon KG Gold Tune TYPE I 10000uf 63v audio will fit nicely. 31mm height available underside of PCB for more caps if need be, same 50mm dia limit.

MF recommend to bypass (shunt) all audio path electrolytics with high grade polypropylene. Good idea?? - I'm not sure

C3: 10uf 50v NP -ELNA NP

C103: 10uf 50v NP -above

C5: 100uf 16v NP -Nichicon ES type

C105: 100uf 16v NP -above

C9: 1uf 63v - Audio cap, panasonic EB or possible PP film still to check DC on board at this location

C109: 1uf 63v -above

C10: 100uf 63v -Fitted ELNA SILMAC II 63v, going to test with Nichicon KZ also - input de-coupling, signal to earth

C110: 100uf 63v above

C11: 100uf 63v -above

C111: 100uf 63v -above

C19: 220uf 10v -ELNA Cerafine

C119: 220uf 10v -above

Replace BR with Schottky diodes RS: 395-2487 or fast recovery diodes RS: 688-2293 (15ns recovery)

Clean board with isopropenol

Replace polyester PSU and supply 'bypass?' caps with high grade polystyrene or polypropylene in large capacitance (wima)

C8 - 104J 250v - Replace with 0.1uf 100v Wima

C20, C21, C22 : 104J 250v - Replace with 0.1uf 100v AC Wima

C120, C121, C122 :104J 250v - Replace with 0.1uf 100v AC Wima

Replace polyester plastic film caps at output with polystyrene K71-4: C18: 0.22uf, C118: 0.22uf

Pure copper noise nulling 'belly band' screen fitted to mains transformer, copper tape. soldered and earthed

Replace internal hookup cables with twist pair. 0.7 mm fine silver (99.99% pure) with teflon screen

Twist mains wires and fit a screen using foil tape and heat shrink

Refurbish sockets, check for wear, replace anyway!

Replace ceramic with polystyrenes

C7: 47pf - NOS 47pf 63V POLYSTYRENE FILM & FOIL CAPACITORS - STYROFLEX CAPACITOR KS - heat sink when fitting

C107: 47pf - NOS 47pf 63V POLYSTYRENE FILM & FOIL CAPACITORS - STYROFLEX CAPACITOR KS - heat sink when fitting

Hot glue fix polystyrenes to reduce vibration

Adjust bias to each side

X4 Fuses: F6.3A L 250v removed & polished

slowly working my way through the list, changing bit by bit and listening for a day or so, longer if burn in time is needed. so far sound is improved (i wont go into BS). Surprising improvement came from the copper band fitted round my toroidal transformers in each of my PSU enclosures. I've got 6 sat about a meter away from my hi-fi, i fitted them all with (20mm) copper bands at the same time and was surprised to hear more bass come through than before. This was cheap so i gave it a bash, nothing to loose, probably wouldn't have believe someone if they had told me, bit 'snake oily'. The band must go completely around the toroid and be soldered to to itself, I ran i cable from it (soldered) to the earth pin on my IEC socket.