|

|

Post by canjunkie on Jun 8, 2008 21:47:28 GMT

Just been experimenting with PCB lacquer to add some extra protection to the tracks. It actually does make a bit of a mess when soldering but the tinning process protects the copper from tarnishing anyway. Things are a bit quieter workwise now as well so I'll sort a thread out in the for sale section tomorrow morning. I've already sold 5  . In case your wondering what happened to your 2nd board, I wasn't happy with it after comparing to the latest batch so I'll do you a new one and whack it in the post no later than Tuesday morning. On the subject of the film I've just bought some of this..... cgi.ebay.co.uk/PCB-Transfer-Paper-IRON-on-etching-picbasic-basic-robot_W0QQitemZ190227283062QQihZ009QQcategoryZ86728QQssPageNameZWDVWQQrdZ1QQcmdZViewItemFor 6 quid including shipping its got to be worth comparing to the 'Press 'n' Peel. I'll let you know how I get on with it. I've also changed over to Sodium Persulphate as an etchant rather than Ferric Chloride. Its translucent so its easier to keep an eye on the progress of the boards but if its not kept above 40 degrees C the etching process takes ages. I re-used the SG system etching bag thingy so if anyone is thinking of having a go at this etching lark I can recommend this little kit. Much less mess  |

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Jun 8, 2008 22:03:18 GMT

Dave

Interesting link. Could be worth trying, especially as my Laser printer has a bit of trouble handling the sligtly wider than A4 sheets of Press 'n' Peel.

Re the change of etchant, be careful when using some of these types where a Dalo pen, or similar, is used for touchups. Ammonium Persulphate, for example, isn't really suitable for use with a Dalo pen. You need to have pretty thick coats.Some suppliers even warn about this.

Alex

|

|

|

|

Post by canjunkie on Jun 8, 2008 22:12:23 GMT

Thanks for the tips Alex. I touched up with Dalo and went over that with CD marker so it had two coats! That seemed to work OK. I'll probably stick to the Sodium persulphate as its more efficient at lower temperatures - I think the Ammonium stuff only works well above 60 degrees. Its also a lot nastier to work with although anyone thinking of getting into this etching lark should take precautions when working with any of the etchants  |

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Jun 9, 2008 6:04:53 GMT

|

|

|

|

Post by PinkFloyd on Jun 9, 2008 11:15:33 GMT

Just been experimenting with PCB lacquer to add some extra protection to the tracks. It actually does make a bit of a mess when soldering but the tinning process protects the copper from tarnishing anyway. Things are a bit quieter workwise now as well so I'll sort a thread out in the for sale section tomorrow morning. I've already sold 5  . In case your wondering what happened to your 2nd board, I wasn't happy with it after comparing to the latest batch so I'll do you a new one and whack it in the post no later than Tuesday morning. On the subject of the film I've just bought some of this..... cgi.ebay.co.uk/PCB-Transfer-Paper-IRON-on-etching-picbasic-basic-robot_W0QQitemZ190227283062QQihZ009QQcategoryZ86728QQssPageNameZWDVWQQrdZ1QQcmdZViewItemFor 6 quid including shipping its got to be worth comparing to the 'Press 'n' Peel. I'll let you know how I get on with it. I've also changed over to Sodium Persulphate as an etchant rather than Ferric Chloride. Its translucent so its easier to keep an eye on the progress of the boards but if its not kept above 40 degrees C the etching process takes ages. I re-used the SG system etching bag thingy so if anyone is thinking of having a go at this etching lark I can recommend this little kit. Much less mess  I've made your JLH for sale post a "sticky" and also an "announcement" so it now appears in all the forums. I hope you sell tons of them CJ cause they really are great little circuits that really do the business. Mike. |

|

|

|

Post by canjunkie on Jun 9, 2008 11:43:22 GMT

Thanks Mike, glad it does the job  I may need another mini hi-fi down in the shed then  |

|

|

|

Post by canjunkie on Jun 9, 2008 20:32:56 GMT

Another little trick to make things easier. I got some 90gsm tracing paper from a local 99p bargain store. It is just as good, if not better, at cutting down friction when laid over the pnp film for ironing. The big bonus though is you can keep an eye on the transfer process   |

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Jun 9, 2008 20:55:38 GMT

What a great idea !  |

|

|

|

Post by PinkFloyd on Jun 9, 2008 21:08:16 GMT

Brown paper is excellent too  |

|

|

|

Post by canjunkie on Jun 10, 2008 20:02:52 GMT

By the way folks, if anyone wants to have a go at etching their own boards just PM me with your email address and I'll send you the artwork. I can send in PDF or WMF at the moment - still working on a set of hi res TIFF's - the conversion utility with my s/ware isn't doing a great job so far!  |

|

|

|

Post by dotnet on Jun 11, 2008 13:50:20 GMT

I got some 90gsm tracing paper from a local 99p bargain store. It is just as good, if not better, at cutting down friction when laid over the pnp film for ironing. The big bonus though is you can keep an eye on the transfer process  Nice tip! I could imagine that baking paper from the supermarket works well, too. It's non-stick and translucent. Cheers Steffen. |

|

jonclancy

Been here a while!  Mr. Ripple Eater

Amateur EAGLEist

Mr. Ripple Eater

Amateur EAGLEist

Posts: 1,131

|

Post by jonclancy on Jun 11, 2008 22:05:21 GMT

Brilliant tips with the paper, Guys!!  I thought it was time the iron came out today and did some toner transfer onto a couple of boards. The quality is great on about half the boards, but some of the others required a repair of 5 with the Lumocolour marker. I lost one board altogether when half of it didn't transfer to the copper. I was going to etch them tonight in the Elcheapo tank, but I checked my FeCl crystals and the bag will only make up about a half litre.  Cobblers!! I need nearly 3 times that volume, so it looks like I'll be ordering some from Rapid and I can get some of that tinning solution as well. I also ordered the cheaper toner transfer paper on eBay (like a white press n peel, apparently), and have got 7 sheets coming at just under a quid a pop. I know the photo paper method is cheaper, but it's just a bit hit and miss. ;D BTW, the artwork I was transferring was very similar to this commercial offering, and already well though of by at least one Grotto resident:  audioupgrades.co.uk/discrete.shtml audioupgrades.co.uk/discrete.shtmlThe original design coming from Ray at Ray Electronics. home.quicknet.nl/qn/prive/ra.vdsteen/outputstage_en.htmlCheers Jon |

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Jun 11, 2008 22:50:36 GMT

Jon

You can often economise on the etchant, if you just cover the PCB with a little less than it's own depth of etchant, kept warm by sitting the etching tray in hot water. (In the kitchen sink if she who must be obeyed isn't home) and continually gently agitating.

BTW, an empty ice cream container is also O.K. to use , and the nice steep sides make it less likely to splatter some on your shirt ! (or spill into the sink!)

Alex

|

|

jonclancy

Been here a while!  Mr. Ripple Eater

Amateur EAGLEist

Mr. Ripple Eater

Amateur EAGLEist

Posts: 1,131

|

Post by jonclancy on Jun 12, 2008 23:04:14 GMT

Hiya Alex! I normally use an old takeaway tub as it has a decent lid on it - saves the splashes a bit!  I just acquired the Sun Hayato etch tank from the Bay and have got a small aquarium pump too. It works fine with water, a nice stream of bubbles. I'm just itching to try out this method as I'm hoping it'll be quicker and I'll have more control over the etching. It seems to be so easy to over etch the boards. ;D I'm after some of those tinning crystals, so I can bung some FeCl onto the order - sod the expense, this is science!!!!  Cheers Jon |

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Jun 12, 2008 23:28:52 GMT

Hi Jon ! All you need now is an aquarium heater to speed it up even more.  BTW, Dave may soon have improved, simpler artwork for an adjustable dual regulated supply. It will likely be around 3" x 2". Keep watching for canjunkie's next line of DIY PCBs. Presently , I am assembling a dual reg JLH with current limiter from one of Dave's artworks. UPDATE:It all went together rather nicely,due to Dave's improved spacing. Alex |

|

|

|

Post by canjunkie on Jun 13, 2008 13:00:16 GMT

I'm raiding my brothers loft over the weekend, he used to keep exotic fish when he was younger  He reckons he got the bubbly thing and a some sort of rubber coated waterproof heater thingy  . This etching thing is a hobby within a hobby  |

|

pagan

<100

How do I activate my account?

Posts: 81

|

Post by pagan on Jun 13, 2008 13:23:32 GMT

|

|

|

|

Post by canjunkie on Jun 13, 2008 14:33:20 GMT

|

|

|

|

Post by canjunkie on Jun 13, 2008 14:54:04 GMT

Mother always says I've got a lot of empty spacing, between the ears  |

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Jun 13, 2008 21:50:24 GMT

Allan

If I made enough PCBs to justify the expense, I would buy one of those from Altronics too.

Alex

|

|

|

|

Post by canjunkie on Jun 14, 2008 15:24:45 GMT

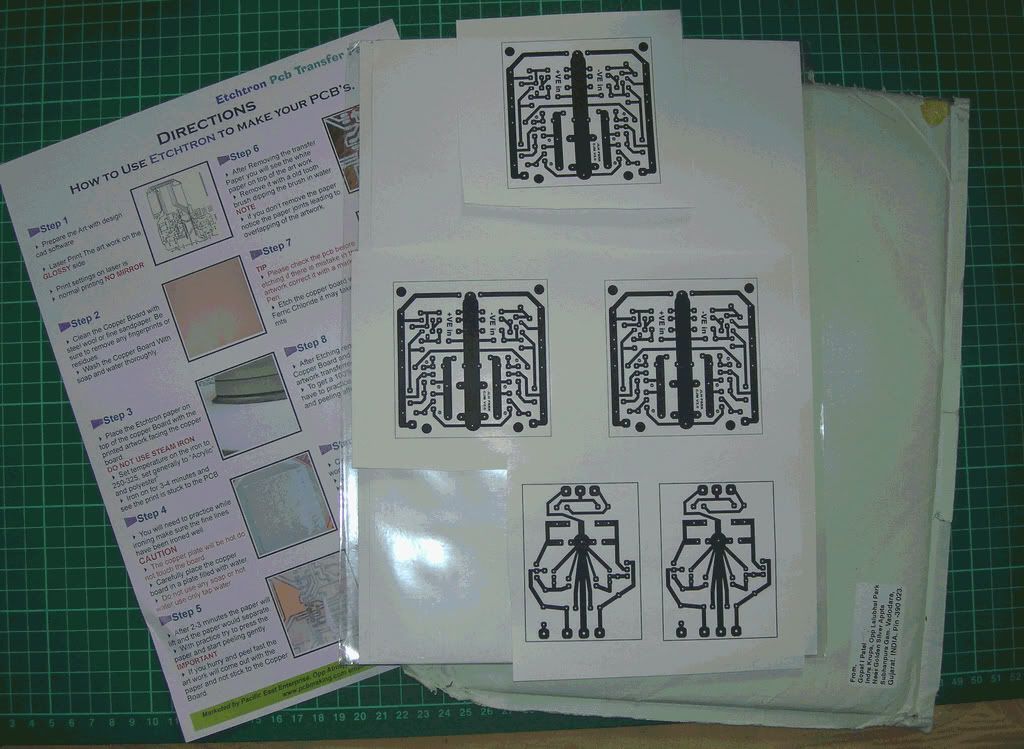

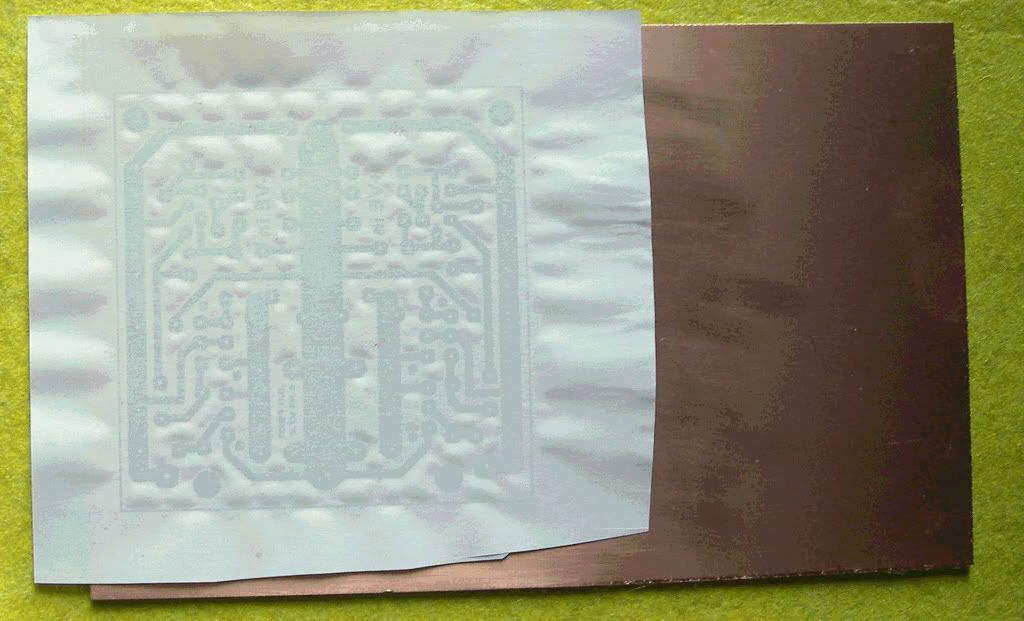

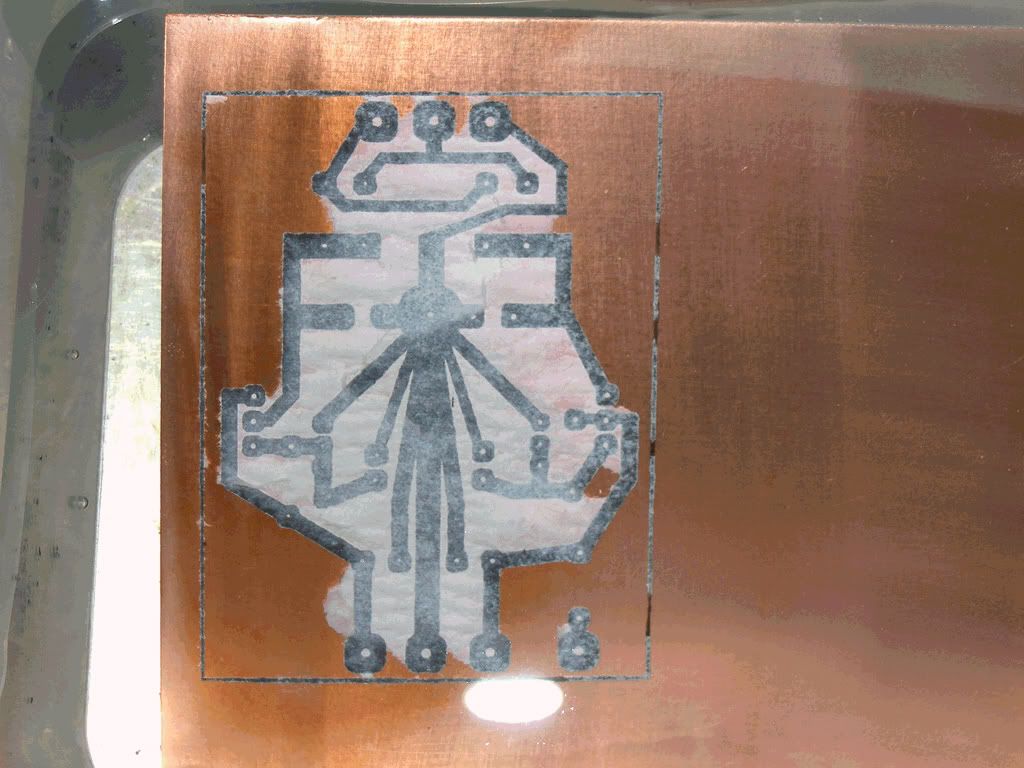

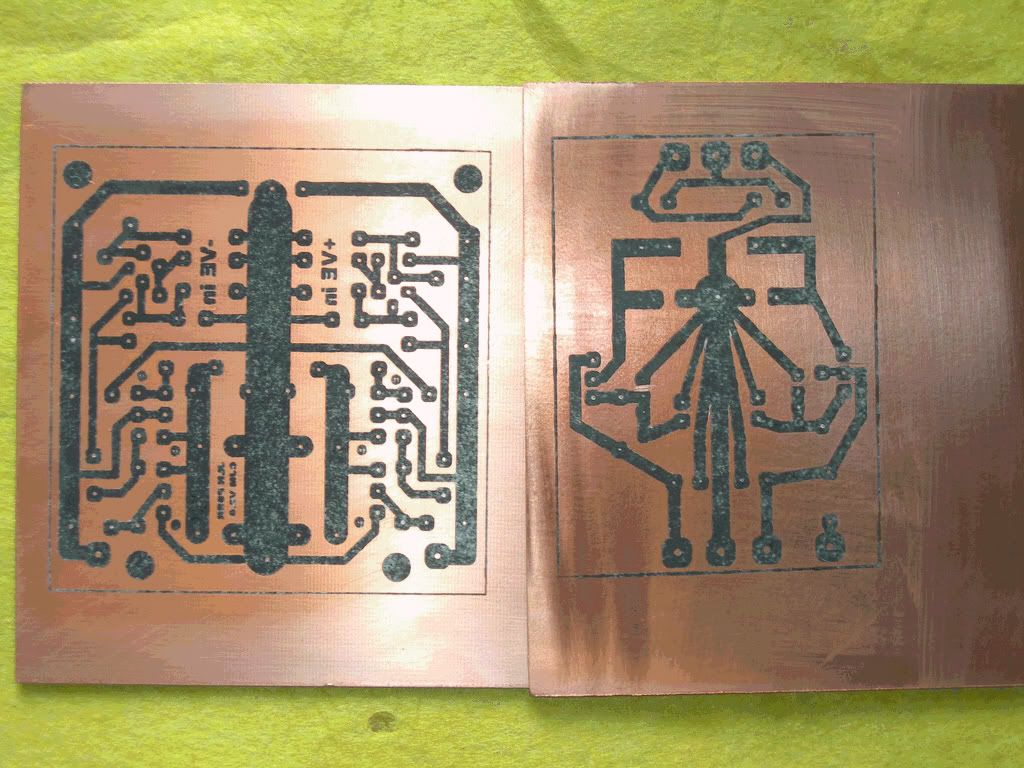

Just got this lot in the post this morning....  Sheet size is A4 which is handy and the instructions were very clear & easy to follow. It also went through the laser printer 1st time with no problems. Ironing was straight forward. After an initial go with the tracing paper you can iron directly onto the sheet as it is paper based. This means you can easily spot misses and you can also apply a bit more pressure than with the blue film without the risk of smudging.  When the board has cooled its 'wet' time. Into some cold tap water and leave to soak for a few minutes. You can then gently peel off the paper backing.  The paper stuck to the board can be removed with the scrub of a toothbrush! The transfer needed no going over with the dalo pen, no misses  I'll trim and etch these to and post the results.  |

|

jonclancy

Been here a while!  Mr. Ripple Eater

Amateur EAGLEist

Mr. Ripple Eater

Amateur EAGLEist

Posts: 1,131

|

Post by jonclancy on Jun 14, 2008 17:11:01 GMT

Hey, good work there CJ!!  I got my paper in the post today. Luckily the guy sent some spare sheets!!! ;D Jammed my trusty Laserjet 4P 3 times before I sussed it using a manual feed and a carrier sheet. I'm trying a travel iron now as my inital results were a bit poor, with some smudging evident. I've cut the discrete output stage boards already, as I scoured them off for another go. I've got a Mk2 board soaking at the moment - fingers crossed!! BTW was a toothbrush enough to remove the paper haze across the board? Cheers Jon |

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Jun 14, 2008 21:46:02 GMT

They don't much like those slightly oversize A4 sheets, do they Jon ?

CJ

Nice work as usual. That sharp pointed instrument comes in handy sometimes, doesn't it ?

Regards

Alex

|

|

|

|

Post by canjunkie on Jun 14, 2008 21:59:08 GMT

Jon, I think the best thing with both types of PnP is to keep the paper path through the printer as flat as possible, which makes your findings with the manual feed make sense. Another thing to watch out for is the 'wet' version curls more than the blue film when it comes out of the printer, so keep artwork away from the edges of the paper (at least 25mm) or flatten under nsome heavy books for half an hour. Yep, you don't know how long its taken me to find a use for that thing  |

|

|

|

Post by PinkFloyd on Jun 14, 2008 22:00:08 GMT

The two boards arrived this afternoon CJ, thank you  Really nice work man, I'll populate the two of them and probably offer one up as a prize in next month's competition  |

|