Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Mar 26, 2008 15:30:38 GMT

Hi, I read somewhere here that more upgrade stories were wanted, but I can't suss the method for inserting photos! Selected "insert image" icon but nowt happens, please cure my stupidity.  Chris |

|

|

|

Post by PinkFloyd on Mar 26, 2008 19:37:39 GMT

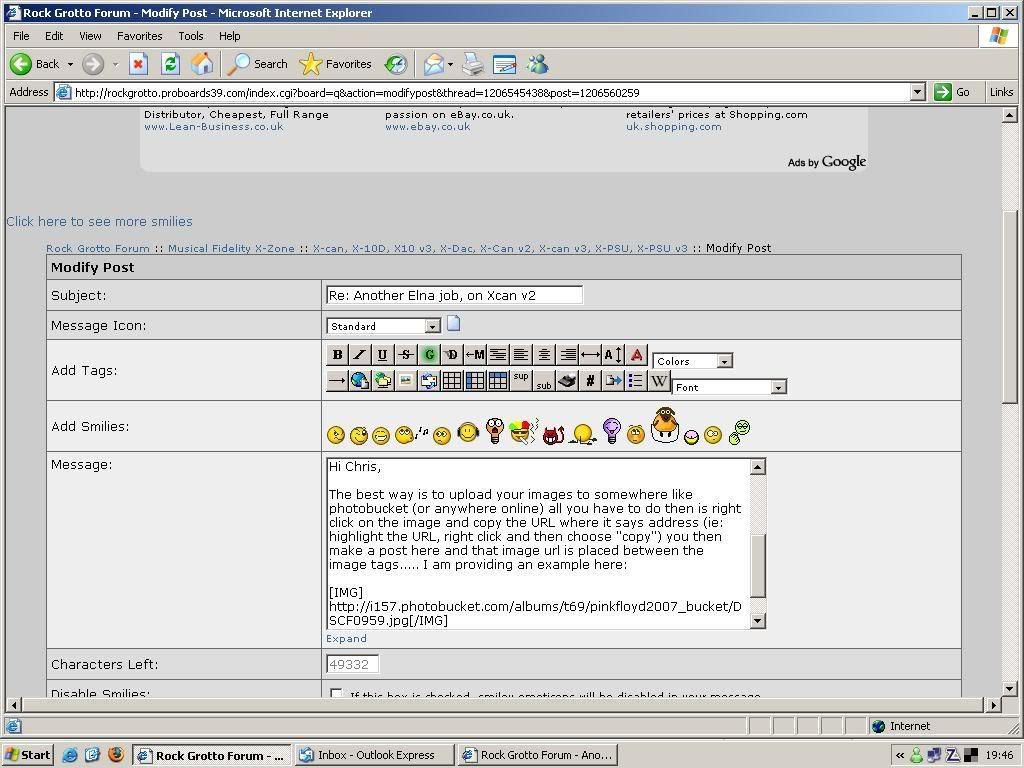

Hi, I read somewhere here that more upgrade stories were wanted, but I can't suss the method for inserting photos! Selected "insert image" icon but nowt happens, please cure my stupidity.  Chris Hi Chris, The best way is to upload your images to somewhere like photobucket (or anywhere online) all you have to do then is right click on the image and copy the URL where it says address (ie: highlight the URL, right click and then choose "copy") you then make a post here and that image url is placed between the image tags..... I am providing an example here: Doing this: (click to enlarge)  Will result in this being displayed:  |

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Mar 26, 2008 23:06:24 GMT

OK, here we go... Carton of bits arrives Monday, thanks Mike. Tuesday, no time, Grrrrrrrrr. Wednesday, morning made free, hoorah! I was going to fit; New valves, cap kit with diodes, Alps vol. and blue light. 1) Undressed her, diginity preserved for photo...  Yeah, I know it's sad but there's very little female influence here. 2) Debagged both boards, with all the advice on the instructions and on the site this was sooooo easy, even for a maniac like me. 3) Repopulated both boards, again pre-armed with said advice this too was very simple. As canjunkie said, being very careful, taking photies, double checking every step, and interuptions, I took nearly 2 hours. (Bet Mike and the other Know- Hows can rattle these off in minutes) Any probs? just one, the red LED. That little wot-not didn't want to come out, after trying various kind and gentle methods and slowly escalating in force, I eventually had to stand on the panel (protected of course) and apply substantial force to shift it! The LED even survived the experience, tough little blighter. BEFORE...  AFTER....  4) Obviously, then re-assembled. Ooooooooh, blue light,  Couldn't wait to plug in. Now I have to admit I was a little scepticle about the druelling praise that has been heaped upon this process, but, wiping severe wetness away from my chin and shirt, I was gobsmacked. My Senn. 580s had bass, oodles of nice, tight, deep bass, were faster and actually exciting to listen to. I am now a firm believer. Hit repeat on the CD player, go and do some work, and let it burn in. Is it really going to get better? Bli'me, I might even buy some better cans at this rate, little pinkie, etc. (hooked). Chris |

|

|

|

Post by PinkFloyd on Mar 27, 2008 8:21:15 GMT

Nice work Chris! erm.... on the one hand we have Miguel with his SUPERSIZE pics and then we have you with your mini pics...... any chance of fattening them up a bit?  yes, the sound will open up over a few days. As to the LED..... get a wooden chopping board, SLAM! the front panel (face first) onto the board and the LED will pop out no problems at all and you will not do any damage to the front panel.... just slam dunk that puppy onto the chopping board and "ping" out she pops  What about the pot, did you trim the shaft? |

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Mar 28, 2008 14:23:08 GMT

OWZAT!

In all the excitement I forgot to trim the pot, so until I need to open her again I've just fitted a felt washer.

One thing I didn't mention, when I dismantled the boards from the case I found the original valves were barely pushed in, a sharp jog could have knocked them out. So even if someone is not replacing any inards, it may be worth checking this.

Chris

|

|

|

|

Post by PinkFloyd on Mar 28, 2008 16:42:09 GMT

OWZAT! In all the excitement I forgot to trim the pot, so until I need to open her again I've just fitted a felt washer. One thing I didn't mention, when I dismantled the boards from the case I found the original valves were barely pushed in, a sharp jog could have knocked them out. So even if someone is not replacing any inards, it may be worth checking this. Chris I wouldn't trim the pot with it attached to the PCB and I certainly wouldn't desolder the pot again as those pads go pear shaped if you keep applying heat to them. Best way to trim a pot is to put the shaft in a vice and hacksaw the surplus off.... as long as it looks ok I'd just leave it mate. |

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Mar 28, 2008 17:41:23 GMT

Thanks for advice, as it looks fine to me I'll leave it well alone.

|

|

|

|

Post by PinkFloyd on Mar 28, 2008 23:27:45 GMT

Or you can use a dremel tool! Yes, you can use a suitable cutter on the end of a dremel but please do remember the heat that is generated in the process and also watch out that the cutter doesn't snatch in the process..... always wear goggles if going down this route ;D Shaft secured in vice and saw off excess with a hacksaw is by far the easiest and best way to go..... To trim a pot "after" fitting to a PCB is bad practice IMO and totally unnecessary. Take off that 8mm BEFORE you fit the pot! |

|

|

|

Post by PinkFloyd on Mar 28, 2008 23:34:32 GMT

I just LOVE the thought and effort that went into this:  SUPERB!! |

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Mar 28, 2008 23:44:32 GMT

Good advice ! And NEVER be tempted to trim the shaft once it's back in the amplifier ! Not even file off the rough end, so that the knob fits properly ! Leave that striped apron for the butchers .  SandyK

|

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Mar 30, 2008 16:05:43 GMT

UPDATE

The Can has been burning in all day for 4 days.(only switched off at night)

This beastie is really loosening up, the bass is still deeper than I heard before but now integrated into the wash of music and treble is much sweeter.

I dug out my Senn 560 II, wow! They NEVER sounded like that before, actually give the 580 a run for their money. At the moment I would say the 560 is better on voices and midrange generally.

I'll keep the burn in process going and compare again.

|

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Apr 7, 2008 22:51:08 GMT

I think the modded xcan is now burnt in as much as is useful.

Piggin' brilliant, really love the improvements, substantial at that.

Even my old 560II sound good. The 580 are now obviously much better across the board, that was until this morning...

I stupidly left them on the floor Sunday night, this morning one 10 year old son "bounced" on them! One ear-piece completely obliterated, AAAAAAAAAAAAGH.

After restraining myself from "bouncing" on my son, I thought, OK chance for an upgrade that the wife can't winge about, every cloud...

Looking around the best deal I've seen is on Ebay for 650s at £189, if anyone knows better please let me know.

|

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Apr 21, 2008 11:15:47 GMT

Just a few more tweaks.... With summer coming and me using the unit more, I was inspired my Mikes cooling techniques, but not liking holes went for slots in the board>  More slots in the casework>  And caps glue flooded>  Hoping I won't need heat sinks on the trannies. That's it for now. |

|

XTRProf

Fully Modded

Pssst ! Got any spare capacitors ?

Posts: 5,689

|

Post by XTRProf on Apr 21, 2008 11:45:12 GMT

Just a few more tweaks.... With summer coming and me using the unit more, I was inspired my Mikes cooling techniques, but not liking holes went for slots in the board>  Hoping I won't need heat sinks on the trannies. That's it for now. Curious. How did you manage to get slot on the casing? Filing and drilling and mixture of both later? Actually, your slots look cool, man! From afar, I wouldn't have notice that the unit is being cooled, retaining the beauty of the original casing. Aesthetically, this is superior to the holes.  Actually, this unit had been designed with the heat in mind and so the tranny will not need cooling. Of course, now with slots, the cooling will be better. If you can get some forced draft in will be better for cooling at the expense of more dirt getting in. |

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Apr 21, 2008 22:53:33 GMT

I wasn't gentle when I cut those slots, the casing is pretty solid. VERY careful use of my trusty, small angle grinder! All burrs were then filed away and the slots tidied with a combination of Dremel and hand file. I have a nice thin diamond blade on the grinder, the fibre type are way too thick. I also wanted to try earthing the cap casings, but can't remember where that thread is  I have a couple of other ideas I'm mulling over, when I decide a sensible way to implement I'll show. |

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Apr 21, 2008 23:07:51 GMT

|

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Apr 21, 2008 23:38:35 GMT

Dog nabit, thankin' you kindly double D.  |

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Apr 29, 2008 21:40:12 GMT

I haven't done the cap earthing yet as I am waiting for some conductive tape. Also, as I only have Senn560's to use at the moment a comparison is far less viable. This gives me the chance to keep the unit disassembled for a while and think of other things to do it! (dangerous???) Next idea rolled out.... Some isolating spikes, in tripod layout. Front view  Rear view  Made sure the rear spike, which is the only one to ingress the enclosure, was well dressed in to avoid any chance of unwanted contact Bottom view  For the moment I've gone with carbon fibre seats for the spikes, until my replacement 'phones arrive and I reassemble for listening tests. |

|

XTRProf

Fully Modded

Pssst ! Got any spare capacitors ?

Posts: 5,689

|

Post by XTRProf on Apr 30, 2008 8:36:22 GMT

Actually, I haven't read anything from that thread before commenting on this. But there is a connection between the negative of the cap and the casing. I'm not sure whether this will create any potential hum problems or shorting. If this is safe, why should the manufacturer encased the E-caps with non conducting plastic? Might as well save on this right? So do be careful and know what you are doing and don't be a terrorist. OMG, we don't want terrorists .......................   |

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on May 5, 2008 13:49:42 GMT

My repalcement 'phones arrived today, found some HD600's in perfect order and partially run in.  Re-assembled the X-cans with cap earthing in place, after making sure all was well with said proceedure. Obviously, 'cos I'm on new 'phones, I had to do some repeated A/B comparisons for the earthed-caps. There was definitely a difference but to my ears the earthing was not favourable. To me the sound was slightly more strident but also a tad muddled. So the caps were returned to normal state. Interesting idea but not for this listener. 'Phones are now continuing their run-in and I hope to be fully familiar with them before a certain L'il Pinkie shows up. |

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on May 31, 2008 12:46:10 GMT

My Little Pinkie arrived a while ago and has been running in since, Mike also sent some parts I was having trouble sourcing, so many thanks for both. As I there was a Jalco HP socket to fit I took the chance to add a couple of minor tweaks I've seen around the forum. To prevent bugs finding the valve glow too attractive through the ventilation slots I've fitted mosquito screen!  Felt pads on the caps...  ...Grommets for the boards  I can't honestly say I heard any difference but I enjoyed the few mins doing it! More importantly the Little Pinkie. When I first plugged in and listened I was surprised by a very different tonal balance on both the HD600 and K701. Warmer and deeper. Now that the LP has bedded in, the character of both 'phones has returned with their individiual strengths enhanced. The 600 bass is tighter and more tuneful with the rest of the spectrum being noticably more open. They are, however, fussier of poor recordings or source (eg mp3 files) getting a bit thrashy in the treble, but of course they are only telling it like it is! The 701 bass has deepened just enough to dispel any of my reservations on this count. Again greater openess/tunefulness is apparent. So thanks again Mike, I'm a happy chappy  Chris |

|

|

|

Post by dotnet on May 31, 2008 15:09:27 GMT

Hi Chris,

how much did you pay for those felt pads? They don't look like the genuine audiophile variety...

I'm a firm believer in the sound-altering capabilities of felt pads, I experienced those myself when I lodged a couple of the pads into my ear canals...

Cheers

Steffen.

|

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Jun 1, 2008 13:15:54 GMT

Steffan,

Nope, can't get the real stuff here. Just thought I'd try the common stuff in the hope it may work.

Felt pads in your ears? Maybe work better after you've removed them again, clean ears!

|

|

|

|

Post by dejanm on Sept 17, 2008 17:17:21 GMT

|

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Sept 17, 2008 21:16:56 GMT

...it also depends on which knob you fit to the new volume pot. The one you see on mine has very minimal gap between it and the front panel, without cutting down the pot shaft. I used a single felt washer to fill the gap to my satisfaction. As this is already prone to double-entendre I'll add that other knobs may not allow the shaft to penetrate to the same depth  thus requiring their shafts to be cut shorter  |

|