nando

Been here a while!  The Frying Dutchman

Always look on the bright side of life

The Frying Dutchman

Always look on the bright side of life

Posts: 393

|

Post by nando on Aug 30, 2016 21:12:08 GMT

Hi there,

I'm a bit of a x-series fan I guess. I have a total 14 X-series components from Musical Fidelity and have for some years now.

As they age there are a few problems. One problem is with my x-cans (v1). The volumeknob is sensitive and then one channel goes poof. The headphone socket cracks a bit too when I touch it. (So don't touch it then, huh?)

Another problem is with my Nu-Vista pre-amp. The "tuner" input does not work at all. I have my x-plora connected to the aux1 input (and working fine) but it's not how is should be.

Any suggestions what to do?

I guess the cause of both problems should be sought in (the soldering of) the circuit board?

Another thing that happens now an then is that the display of my x-plora (lack of a better word) shivers and the text and numbers shake a bit. It happened a couple of times and I don't know what the condiotions were at that moment. What could this be?

|

|

|

|

Post by PinkFloyd on Sept 1, 2016 20:17:02 GMT

Hi Nando, I can help with the X-CANS (V1) problem but need a bit more information....... when you say "The volume knob is sensitive and then one channel goes poof" what do you mean? Does one channel cut out? "The headphone socket cracks a bit too when I touch it." That could be anything from DC on the output to an intermittent solder joint on the headphone socket. If it only occurs when you touch your headphone jack then I would suggest that one or more of the solder joins that connect the headphone socket to the circuit have broken. This is actually quite common in "well used" X-CAN amps that have had a lot of jack insertions, the headphone socket isn't mechanically secured to the front panel so every single time you insert the headphone jack it causes movement of the headphone socket. Over time this can lead to a hairline crack on the joint and the remedy is to desolder the headphone socket and then resolder it with some good quality 60/40 solder. There are three pads, desolder one and then flood in fresh solder..... then desolder the second pad / flood in fresh solder and then do the same for the third pad. Thats should cure that but if not it could be the headphone socket itself. They are relatively cheap to buy (I sell Jalco Pro ones which are superb) but also pretty easy to repair. Look inside the "hole" where you insert the jack....... on the bottom you will see a metal contact....... This is pretty much designed to always make contact with the jack but over the years it can lose its tension so it's a simple matter of inserting an implement of your choice and prising it "upwards" in order to re-tension it. I don't know where you live but if you're within a ten mile radius of me / KW14 7RL / I'll be happy to come round and help you  Take the front and rear panels off, slot the boards out (from the front) and take a few photos (close up / Macro) of the boards and I will be able to see if there's anything obvious that's causing the "poof". Before you do that though, I also want you to swap the valves (tubes) over...... pull them out (with a gentle rocking motion) and swap them over...... if the "poof" migrates to the other channel then you know the valves are knackered and time to replace them with a minty fresh new pair. If they are the original valves that came with the amp then they will most definitely have drifted WAY out of spec over the years of usage..... you should really replace your valves every 500 hours or so but nobody does, they assume they are fine because they are "glowing" but they're not...... they are nothing like light bulbs (lamps) and the thermionic valve (tube) will glow forever but has drifted so far out of spec it's pretty much useless for the intended job in hand. Let's see inside the amp Nando, as I say, It may be something obvious like a dried out cap (but even then, they are not "obvious" and may require an ESR tester to establish if they have gone high Z. That's the best advice I can give you from my computer screen Nando. With regard to the other questions, I am not au fait with the other items you have problems with. I'll ask Leo if he can chip in on those, he's a lot more wide ranging than me when it comes to things like this. Best regards and welcome to the forum. Mike. |

|

nando

Been here a while!  The Frying Dutchman

Always look on the bright side of life

The Frying Dutchman

Always look on the bright side of life

Posts: 393

|

Post by nando on Sept 3, 2016 10:53:27 GMT

Hi Mike, I'm pretty shure I don't life within 10 miles of you as I live in the Netherlands. I allready made some photo's of the inside of the x-cans. I thought the underside looks a bit messy around the solderjoints, but I'm not an expert. What do you think?  I can swap the tubes and replace them alltogether as I bought some others some years back. They have Phillips JAN (USA made) ones in them now and I have some Phillips JAN (also USA made) as spares. I have a x-pre and two x-d10's that use the same tube, not?    |

|

|

|

Post by PinkFloyd on Sept 3, 2016 19:51:18 GMT

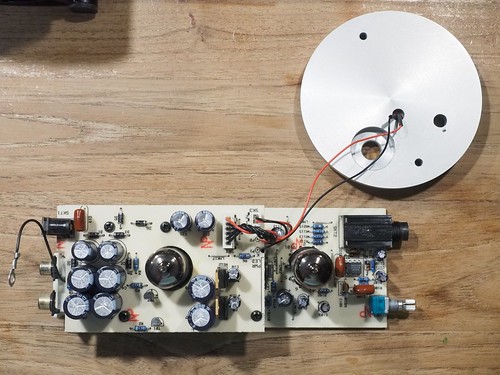

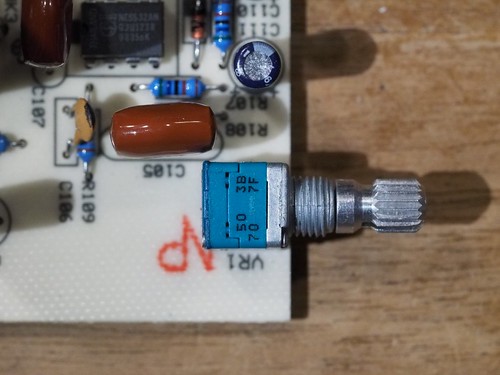

Hi Nando, It "may" just be the angle at which the photo was taken but one of the joints on the potentiometer looks like it has broken:  I would flood a small amount of solder into the joints and see if that remedies the intermittent problem with the potentiometer / volume control. If the amp has been used a lot then it will definitely need new valves..... if they are the originals then they will be absolutely useless by now, in fact you should ideally renew your valves every 700 hours or so. They will "glow" for years but that doesn't mean they are working within their parameters, the values start to drift out of spec and the sound quality also deteriorates. Replace them with new ones. The caps in the X-CANS (V1) also have a habit of going high ESR..... the X-CANS is over 20 years old so a re-cap is always a good idea. If you don't want to re-cap the entire amp then the ones that will have probably gone high ESR are the four that are adjacent to the regulators:  The stock X-CANS utilizes 85C general purpose caps..... the four I am pointing to in the above image are 2 x 1,000uF / 35V and 2 x 100uF / 35V..... all of them are 85C types. Your V1 appears to be one of the early ones, if I'm not mistaken the blue caps are "TEAPO" types? You want to be replacing these with 105C rated capacitors...... Panasonic FC or FR are very good. To sum up..... resolder both the headphone socket and the potentiometer / volume control, replace the valves with new ones, ideally replace ALL of the electrolytic capacitors with 105C types but if funds are tight begin with the four I have pointed to. Your problem will be cured. All the best, Mike. |

|

leo

Been here a while!  Team wtf is it?

Team wtf is it?

Posts: 3,638

|

Post by leo on Sept 3, 2016 20:16:48 GMT

I don't know the x-plora but have you tried lightly tapping the side of it when the display has issues ? Does this make any difference ? I'd try and eliminate obvious things like dry solder joints or poor connections . Also check the driver circuitry for the display , these things can get warm sometimes causing problems if not properly cooled .

|

|

leo

Been here a while!  Team wtf is it?

Team wtf is it?

Posts: 3,638

|

Post by leo on Sept 3, 2016 20:24:21 GMT

For dry solder joints or fractures on low voltage circuitry I put my thumb pad on the joints and gently press the component with my finger, you can sometimes feel if theres a loose connection on the joint . A multimeter helps too just test the circuit tracks from joint to joint for bad connection due to dry joints or fractured joints. It can be a long process especially if the problems are intermittent

|

|

nando

Been here a while!  The Frying Dutchman

Always look on the bright side of life

The Frying Dutchman

Always look on the bright side of life

Posts: 393

|

Post by nando on Sept 23, 2016 21:30:11 GMT

Thanks for the reply's.

If the x-plora display acts up I'll tap it. But what does this do? If the display is normal again, it means that the soldering is bad?

I have Phillips JAN tubes in the x-cans. What are the original tubes in the x-cans?

I talked to a audio shop owner and he questioned if there would be spare parts for the headphone socket and the potentiometer. Looking at this forum I think this nonsense.

I'll ask my father to help me solder up the joints in the x-cans like you pointed above.

|

|

|

|

Post by PinkFloyd on Sept 24, 2016 23:19:47 GMT

I can supply the headphone socket and potentiometer  |

|

|

|

Post by PinkFloyd on Sept 24, 2016 23:23:49 GMT

The original valves (tubes) fitted were JAN / Philips 6922 and will be well knackered by now....... absolutely certain about that.

|

|

nando

Been here a while!  The Frying Dutchman

Always look on the bright side of life

The Frying Dutchman

Always look on the bright side of life

Posts: 393

|

Post by nando on Sept 25, 2016 18:19:27 GMT

I can supply the headphone socket and potentiometer  Yes, this is what I will do. My father has been soldering about 40 years so we will do the job together. I think I will have the x-cans kit and the potentiometer and headphone socket. Then why not the tubes, right? But I am a bit confused about the available upgrade kits for my x-cans. There is the capacitor upgrade kit, the extra and then the opamp replacement... choices, choices, confusion. I don't have a soldering iron and my father neither, he is retired and has non of himself. Can you recommend a soldering iron which does not break the bank. By the way. I had a listen to the Jenkins Float headphones. Not ideal circumstances but impressed by the performance non the less. |

|

|

|

Post by PinkFloyd on Sept 25, 2016 19:12:13 GMT

I can supply the headphone socket and potentiometer  Yes, this is what I will do. My father has been soldering about 40 years so we will do the job together. I think I will have the x-cans kit and the potentiometer and headphone socket. Then why not the tubes, right? But I am a bit confused about the available upgrade kits for my x-cans. There is the capacitor upgrade kit, the extra and then the opamp replacement... choices, choices, confusion. I don't have a soldering iron and my father neither, he is retired and has non of himself. Can you recommend a soldering iron which does not break the bank. By the way. I had a listen to the Jenkins Float headphones. Not ideal circumstances but impressed by the performance non the less. Hi Nando, There is only one upgrade kit for the X-CANS..... this one: www.rock-grotto.co.uk/v1upgradekit.html I haven't updated that page in a while, the latest version is the same price and really takes the X-CANS (V1) to a whole new sonic dimension. A new pair of tubes are essential, that goes without saying. The NE5532 opamps in the V1 aren't too bad but can be bettered with something like the OPA2132 / OPA2134....... you would fit turned pin DIP 8 sockets, that way you could try a lot of different opamps out without having to desolder them every time. From past experience, the likes of OPA2132, OPA2134 / OPA2227 sound great in the V1 and are drop in replacements for the NE5532. If you're only going to do this one job then there's no point investing in an expensive soldering station Nando..... what's your minimum / maximum budget for a soldering iron? When I know that I can advise you better. Best regards, Mike. |

|

|

|

Post by PinkFloyd on Sept 25, 2016 19:15:52 GMT

By the way, whereabouts in the world are you Nando?

Mike.

|

|

nando

Been here a while!  The Frying Dutchman

Always look on the bright side of life

The Frying Dutchman

Always look on the bright side of life

Posts: 393

|

Post by nando on Sept 26, 2016 12:36:26 GMT

By the way, whereabouts in the world are you Nando? Mike. I send you an e-mail with some questions. Hope there is no confusion. I live in the Netherlands. |

|

nando

Been here a while!  The Frying Dutchman

Always look on the bright side of life

The Frying Dutchman

Always look on the bright side of life

Posts: 393

|

Post by nando on Apr 23, 2017 17:52:16 GMT

So today I finally modified and repaired my x-cans. I ordered the whole package and installed it with my father. Now retired, he has some 30 years experience soldering many measuring devices for concrete factories. He taught me how to do proper soldering today.

I thought this job would be more difficult but there is logic to it.

We replaced the socket and potentiometer as well as the caps, valves and diodes. My x-cans are good for another 20 years!

|

|

|

|

Post by PinkFloyd on Apr 23, 2017 18:42:47 GMT

So today I finally modified and repaired my x-cans. I ordered the whole package and installed it with my father. Now retired, he has some 30 years experience soldering many measuring devices for concrete factories. He taught me how to do proper soldering today. I thought this job would be more difficult but there is logic to it. We replaced the socket and potentiometer as well as the caps, valves and diodes. My x-cans are good for another 20 years! Hi Nando, Well done, I'm glad it went without any difficulties. Give it a few days for the caps to form and you will hear a big improvement in the sound quality. Mike. |

|

nando

Been here a while!  The Frying Dutchman

Always look on the bright side of life

The Frying Dutchman

Always look on the bright side of life

Posts: 393

|

Post by nando on Apr 23, 2017 19:26:26 GMT

Thanks! It was a bit of a puzzle with tha manual because there is the original, the revision and a paper on new capacitors (?). But we managed ;-)

Although it took me all day today it was a good lesson for me.

Now I've seen how to do it, are there other projects for my setup?

x24-k for instance? I use this a lot for connecting my tv, apple tv and playstations to my MF set.

Or the x-psu? This thing only has a transformer inside. Adding caps to it to improve the signal to all the other x-stuff?

And then there are my, x=plora, x-ray, nu vista pre, x-pre, x10d (not much used), x-tone, x-lps. I guess all of them have (20 year old) caps and diodes. But the question is which fit the housing and are an improvement.

|

|