|

|

Post by tontonjok on Oct 11, 2014 16:18:40 GMT

Hello all,

I have a Xcan V3 getting dust since I have a problem with the sound

When I listen to the amp mostly after being turned on, the sound is getting weird like I'm losing bass and sound like a speaker with a torn membrane

I tried to change the tubes but same issue

Your help is very welcomed

|

|

|

|

Post by PinkFloyd on Oct 13, 2014 18:47:50 GMT

Hello all, I have a Xcan V3 getting dust since I have a problem with the sound When I listen to the amp mostly after being turned on, the sound is getting weird like I'm losing bass and sound like a speaker with a torn membrane I tried to change the tubes but same issue Your help is very welcomed Hi tonton, Have you just swapped the tubes over (to different sides) or did you replace them with another pair? Is the distortion on only one channel or on both? It could be one or more of the power capacitors, if you're getting it in both channels but it could also be a number of different things. Have a good close look at the components, are any of the capacitors bulging? are there scorch marks anywhere on the board? If you have a multimeter, set it to the AC range and measure the AC output of the wallwart. There are 3 pins, probe between the two outer pins and the reading should be between 26 - 27 volts. Probe between the centre pin and the left outer pin, the reading should be between 13 - 13.5 volts and then probe between the centre pin and right outer pin... the reading should be between 13 - 13.5 volts. Let's make sure, for starters, that the wallwart is OK. Mike. |

|

|

|

Post by tontonjok on Oct 14, 2014 17:42:02 GMT

Hi Mike

I tried new tubes, and yes it is on both sides when it happens

It could remain 5 or 10 mn and then everything comes back to normal for a while

I checked inside but don't see anything special, I'm not experimented at all but no trace of burn

|

|

|

|

Post by tontonjok on Oct 14, 2014 17:46:15 GMT

By moving the plug in the amp left and right it could get back to normal more quickly but not sure about that The problem is getting worst than before by lasting longer It occurs more after plugging the amp A defective wallwart may a be possible reason I'll ask a friend about that Thanks  |

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Oct 14, 2014 22:36:09 GMT

By moving the plug in the amp left and right it could get back to normal more quickly but not sure about that The problem is getting worst than before by lasting longer It occurs more after plugging the amp A defective wallwart may a be possible reason I'll ask a friend about that Thanks  Are the heaters of the valves still alight when it fades out ? You will need to have the cover off to check that.

|

|

|

|

Post by PinkFloyd on Oct 15, 2014 9:21:28 GMT

By moving the plug in the amp left and right it could get back to normal more quickly but not sure about that The problem is getting worst than before by lasting longer It occurs more after plugging the amp A defective wallwart may a be possible reason I'll ask a friend about that Thanks  What plug are you moving left to right? The main power input plug? If that is the case then it sounds to me you may possibly have an intermittent / loose connection somewhere and it's most likely to be one (or more) of the solder pads on the 3 pin DIN socket. You won't necessarily see any problems with the naked eye as all it takes is a hairline break in the joint for intermittent problems to start occurring. Get yourself a soldering iron and flow some solder into the three solder joints that secure the 3 pin DIN socket onto the board. If it's the headphone "plug" that you are moving from left to right then do what I have just suggested, flow some more solder into the three headphone socket solder pads and this should clear up your problem. Get a hot soldering iron, place the tip on one of the pads until the solder melts and feed in a small amount of fresh solder.... repeat this for all three pads. As soon as we know what plug it is that your "wiggling" it will be a lot easier to pinpoint the fault  All the best, Mike. |

|

|

|

Post by tontonjok on Oct 15, 2014 17:04:43 GMT

The main input power plug indeed, I'll bring the amp to a friend's house to measure the wallwart and fix the 3 pins hoping it'll solve the problem I'll check about the lights during the bug too  I have some E188cc valvo with the amp do you know the price of those ?? |

|

|

|

Post by PinkFloyd on Oct 15, 2014 19:50:11 GMT

The main input power plug indeed, I'll bring the amp to a friend's house to measure the wallwart and fix the 3 pins hoping it'll solve the problem I'll check about the lights during the bug too  I have some E188cc valvo with the amp do you know the price of those ?? It's common sense tonton, If you "wiggle" the main input socket and things get, temporarily, better then there is obviously an intermittent connection at this point. This is the FIRST item to look at, not the last  The 3 pin DIN socket is not secured to the chassis so every time you plug in the 3 pin DIN plug there is movement and this movement will, eventually, stress the solder joins to the point that they will break one united bond and separate into a kind of non permanent bond that will sometimes make contact and other times not make contact. This is known as an intermittent / unreliable bond and the only fix is to make sure that the 3 pin DIN socket pins are securely soldered to the pads. The best way to do it is to get a desolder pump (very cheap)...... apply some heat (with a hot soldering iron) to each solder joint and as soon as the solder becomes liquid then suck it up with the desolder pump....... do one at a time...... as soon as you have desoldered the joint, inspect it to ensure the pad is still intact with the track and (if it is) then resolder the joint with fresh solder...... it's a simple fix but many people look further down the line and waste a lot of time / money replacing EVERYTHING holus bolus getting no further forward. The thing that you are wiggling...... the three pin DIN socket is the culprit, I'll bet my hat on it! It has THREE solder joints holding it in place and I can assure you that they need resoldering. The "distortion" you are hearing is a lack of power and that lack of power is happening because the 12-0-12V AC is only coming online intermittently..... your "wiggle" helps it, temporarily, but as soon as you stop wiggling it distorts again. A CLASSIC case of "three" solder joints that have become hair line crack mobile........ If you need a photo of "where" to reflow the solder then I'll show you but I think it's quite straightforward for you. I am (based on your info) 99.9% sure that the problem is caused by dry joints on your 3 pin DIN AC power inlet Socket. Hope this helps. Mike. |

|

|

|

Post by PinkFloyd on Oct 15, 2014 19:57:42 GMT

I have some E188cc valvo with the amp do you know the price of those ?? That's much like a Philips Miniwatt (E188CC), I haven't got a clue about the price Tonto as I don't bother with knackered valves sold as "NOS", I stick to what I know. All the best, Mike. |

|

|

|

Post by PinkFloyd on Oct 15, 2014 20:29:30 GMT

I have some E188cc valvo with the amp do you know the price of those ?? Anywhere from 99 pence to the moon dependant on the salesman. |

|

|

|

Post by tontonjok on Oct 16, 2014 17:50:49 GMT

Thanks for your knowledge, I'll do all that soon when my friend will have time, Yes a picture showing where to reflow the solder would be very welcomed Have a very nice day  |

|

|

|

Post by PinkFloyd on Oct 16, 2014 19:26:36 GMT

Thanks for your knowledge, I'll do all that soon when my friend will have time, Yes a picture showing where to reflow the solder would be very welcomed Have a very nice day  Hi Tonton, You don't really need a photo as it's pretty much self explanatory...... the three pin DIN socket (where you plug your 3 pin plug into) has three solder connections on the underside of the PCB..... all you have to do is melt the solder on each of these three joints and feed in a small amount of solder.... all you are doing is reflowing / re-soldering each joint. If you have a dry / intermittent / mobile joint at the AC power input that "makes and breaks" then it is only inevitable that your 12 volts AC (or 12-0-12V) will become intermittent and this, in layman's terms, means that you amp will receive 12V for a few seconds, nothing for a few seconds, 12V for a few seconds, nothing for a few seconds etc. etc. etc...... this, in turn, will lead to voltage starvation and will manifest itself as that "torn speaker" type distortion you referred to. The fact that it becomes ok for a while when you "wiggle" the DIN plug would suggest that it's a hairline crack between pin and solder joint and your wiggling is simply making the pins come into contact with the solder joint hence "making" the connection. It's a simple fix and, as I said, just a matter of applying a hot solder iron (300C - 400c or so)to each joint, wait for the solder to melt and then feed in about an extra 5mm of fresh solder. My preferred way of doing it would be to desolder all three of the joints and then redo them with fresh solder BUT the way I have suggested is just as good and possibly easier to a novice solderer. Mike. |

|

|

|

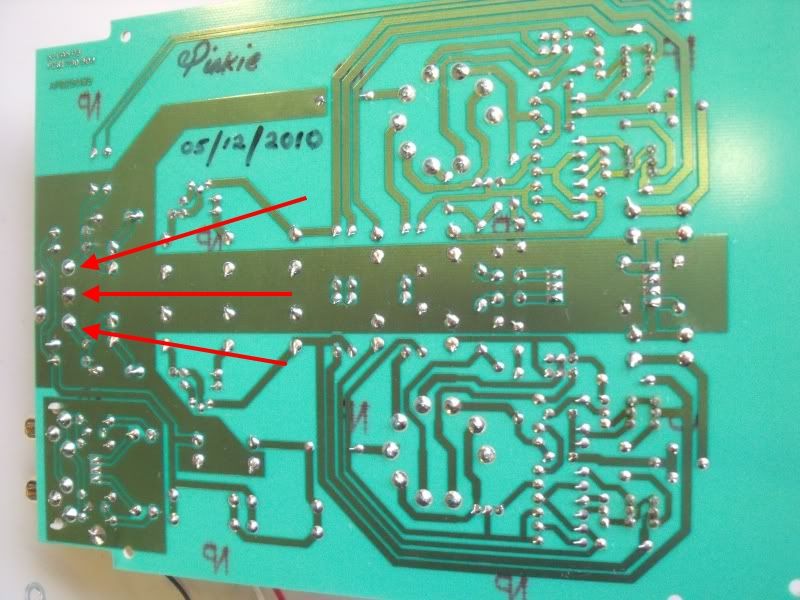

Post by PinkFloyd on Oct 16, 2014 19:39:04 GMT

Christ, I didn't have the arse end of a V3 to hand so had to trawl through the "work in progress" thread but...... voila!..... managed to find one  The three joints you want to resolder are highlighted with red arrows:  |

|

|

|

Post by PinkFloyd on Oct 16, 2014 19:59:50 GMT

Just out of interest tonton....... do you plug and unplug the amp quite often? I ask this because the 3 pin DIN socket is not secured to the chassis and every single time you unplug, or plug in, there is movement and flexing of socket and this, invariably, leads to a parting of solder integrity between the socket pins and the PCB pads. The headphone socket is clamped onto the fascia with a nut, the quad phono socket is secured to the rear panel with a screw but the 3 pin DIN socket is basically "floating", unsupported by anything, and is a prime candidate for leaving the party early, especially if it is subjected to a lot of "ins and outs"  I have come across quite a lot of these and my advice is to always switch the wallwart off at the mains socket rather than pull the DIN plug out of its socket at the amp. Mike. |

|

|

|

Post by tontonjok on Oct 17, 2014 17:12:56 GMT

Yes when I was using the amp I was indeed plugging it in and out all the time from the back of the V3, I'll remove the wallwart at the main socket from now on

Thanks for the clear explanations seems easy to handle

|

|

|

|

Post by PinkFloyd on Oct 17, 2014 19:33:13 GMT

Yes when I was using the amp I was indeed plugging it in and out all the time from the back of the V3, I'll remove the wallwart at the main socket from now on Thanks for the clear explanations seems easy to handle That explains it TonTon, the more times you plug and unplug at the DIN socket the more likely you are to weaken the solder joins and will end up with a dodgy connection. You should always switch off at the mains socket anyway..... it's never a good idea to pull out / insert a plug with the power on..... always ensure the plug is connected and then switch on at the mains outlet. As previously explained, the 3 pin DIN socket is not secured to the back of the chassis so every time you push or pull it, it puts strain on the solder connections which eventually break. When resoldering the DIN socket use a 60 / 40 leaded solder. The solder MF use on the V3 is unleaded and they use way too little on this particular component which is probably a form of built in obsolescence..... you can actually pull the DIN socket off the board without desoldering it which is testament to how crap it was soldered on in the first place! In fact, you can also pull all of the capacitors off of the board without desoldering them which is also pretty damned poor! MF use a soldering technique which used to be called "pin witness".... it was a Canadian standard which made it easier for components to be replaced in the field (in military service for example)...... the idea being was that the component could be quickly and easily removed. The only problem with pin witness is that it is the weakest type of joint and certainly not reliable if the joint is prone to pressure or flexing of any sort. I've just done a quick diagram to show you what I mean:  The pin witness technique is fine and dandy but what happens when (as in your example) there is constant flexing or movement on the joint? The pins part company with the solder, that's what! My preferred soldering technique is to bend the legs over, flush with the board, and this does three things....... firstly it ensures the legs make a physical connection with the solder pads, secondly it ensures that the solder bond is a lot stronger and thirdly it ensures that any "flexing" of the board will not result in a breach of integrity in the join. Just my two cents and the way I have always soldered..... I was trained to Canadian military standards but, in my opinion, that is very flawed and ONLY applicable if the components you are using are prone to failure on a regular basis (which they possibly were back then)....... in an audio application I always go physical mechanical, pin to pad, connection and then supplement with solder. Hope this helps. Mike. |

|

|

|

Post by PinkFloyd on Oct 17, 2014 20:24:11 GMT

Let us know if soldering those three pads fixes the problem tonton.

All the best,

Mike.

|

|

|

|

Post by tontonjok on Oct 18, 2014 16:41:59 GMT

Let us know if soldering those three pads fixes the problem tonton. All the best, Mike. I guess you'll keep your hat a little more  I desoldered all three of the joints as you suggested (used a pump) and put some new solder on, then melted others at RCA, headphones and few more...  I turned the unit on and for now everything is working fine You are the best and really appreciated your help My amp will be available for listening sessions and I didn't waste a lot of time / money trying to fix it Have a very nice day Mike and sandyk |

|

|

|

Post by mrpharmacist on Oct 18, 2014 19:37:04 GMT

This is such a cool site =)

|

|

|

|

Post by PinkFloyd on Oct 18, 2014 19:53:19 GMT

Let us know if soldering those three pads fixes the problem tonton. All the best, Mike. I guess you'll keep your hat a little more  I desoldered all three of the joints as you suggested (used a pump) and put some new solder on, then melted others at RCA, headphones and few more...  I turned the unit on and for now everything is working fine You are the best and really appreciated your help My amp will be available for listening sessions and I didn't waste a lot of time / money trying to fix it Have a very nice day Mike and sandyk Hi TonTon, Glad to have been of help and even happier that you can now enjoy your music once again. All the best, Mike. |

|

|

|

Post by PinkFloyd on Oct 18, 2014 20:05:24 GMT

This is such a cool site =) It could even be as cool as it was a few years ago if we all put some effort into our posts  Mike. |

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Oct 18, 2014 21:29:19 GMT

This is such a cool site =) It could even be as cool as it was a few years ago if we all put some effort into our posts  Mike. Better still, would be if more members just posted occasionally about their various interests. |

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Oct 18, 2014 21:42:25 GMT

Let us know if soldering those three pads fixes the problem tonton. All the best, Mike. I guess you'll keep your hat a little more  I desoldered all three of the joints as you suggested (used a pump) and put some new solder on, then melted others at RCA, headphones and few more...  I turned the unit on and for now everything is working fine You are the best and really appreciated your help My amp will be available for listening sessions and I didn't waste a lot of time / money trying to fix it Have a very nice day Mike and sandyk Thanks Tontonjok Mike has many years of experience with many Musical Fidelity products, both repairing them and upgrading them to better sounding than new using high quality components. Mike also supplies higher quality power supplies for many of them too, that are hand made to order in Scotland, as well as having a huge inventory of unused premium quality valves at better than average pricing, and will match them as pairs to closer tolerances than most suppliers do.

Kind Regards Alex

|

|

|

|

Post by mrpharmacist on Oct 18, 2014 23:47:25 GMT

I thought it was really quite special how someone could have a problem with a component 'remotely diagnosed', self-fixed and it all touch on history regarding military standards. Keep the music going =)

|

|