Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Dec 17, 2007 9:37:21 GMT

"That's for better noise figure, right?"

No hum loops that way.

BTW, did you try to cancel out most of the effect of the buffer's half wave rectification on the transformer, by loading the secondary winding with an oppositely connected diode and load resistor ? Even with separate transformers, it could be worthwhile trying? Lots of little things can add up.

Alex

|

|

XTRProf

Fully Modded

Pssst ! Got any spare capacitors ?

Posts: 5,689

|

Post by XTRProf on Dec 17, 2007 11:37:06 GMT

"That's for better noise figure, right?" No hum loops that way. BTW, did you try to cancel out most of the effect of the buffer's half wave rectification on the transformer, by loading the secondary winding with an oppositely connected diode and load resistor ? Even with separate transformers, it could be worthwhile trying? Lots of little things can add up. Alex Err, I thought the 2 diodes in the X V3 series equipment already is giving full wave rectification? That's why we need to use the CT way which reduces effective VA of trans to half for doing that. Please elaborate. I'm learning ............  |

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Dec 17, 2007 12:03:52 GMT

XTRProf Sorry, my mistake. I was thinking of the X10-D Tube buffer, which of course uses a single 12VAC supply.  I haven't seen the schematic of the later one, so I can't be sure whether it still draws more on one half cycle, than the other. I was thinking of the thread " Musical Fidelity X10-D transformer question" which you were also involved in. SandyK |

|

XTRProf

Fully Modded

Pssst ! Got any spare capacitors ?

Posts: 5,689

|

Post by XTRProf on Dec 17, 2007 12:15:24 GMT

XTRProf Sorry, my mistake. I was thinking of the X10-D Tube buffer, which of course uses a single 12VAC supply.  I haven't seen the schematic of the later one, so I can't be sure whether it still draws more on one half cycle, than the other. I was thinking of the thread " Musical Fidelity X10-D transformer question" which you were also involved in. SandyK OIC. No problem, man ..........  The V3 series should be using the 3 pin CT way as the X-PSU V3 4 din outputs are with 3 pins. Fyi.  |

|

XTRProf

Fully Modded

Pssst ! Got any spare capacitors ?

Posts: 5,689

|

Post by XTRProf on Dec 26, 2007 7:06:15 GMT

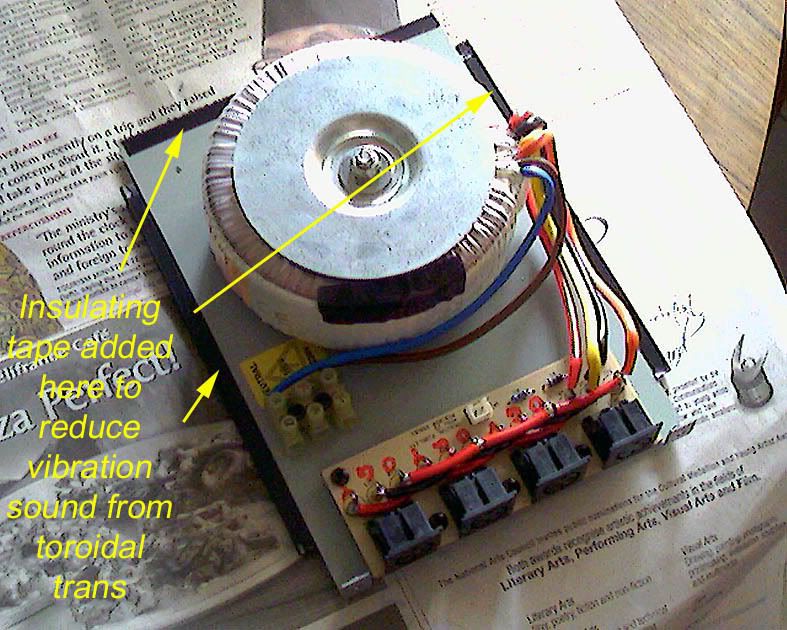

Now to post the rest of the pictures, done last week, to fully "commission" this reborn X-PSU V3. All are considered improvements to what were provided. Switch With Fuse  Decoupling the trans from the main case to reduce trans vibration transmission to the case ...........  Of course, you can also spray those tar dampening compound for car undercoat to the chassis internals to reduce vibration noise further. I didn't do it as I find it quite messy. The final product compared to the original ...........   Isn't she lovely and original when compared to the original? With these "improvements" added I could swear the sound now seems even less digital and more analogue now.  Ho, ho, ho ............. Merry Christmas to all ...............  |

|

|

|

Post by aurum on Dec 26, 2007 22:51:25 GMT

Hi XTRProf If you look at the archives you will see some of the improvements I made to the X-PSU V3. rockgrotto.proboards39.com/index.cgi?board=q&action=display&thread=11699841201. Take the bolt out the center of the transformer & replace it with a non ferrous type, like brass or stainless steel 2. take the steel cups that hold transformer in place & replace with copper. 3. I dampened the transformer directly using cork sheet cut to size, then sandwiched the copper together. I think you will find this a superior method to what you suggested. 4. I put an X2 class cap across the mains & neutral leads. I forget the value but it is in the discussion. That one you have to experiment with, as it is more down to the bugs in your power supply & musical taste. 5. I originally put a by-bee filter in mine but after all the other mods I made it sounded better without it. Don't think they don't work they do. If you try these suggestions then you can expect further improvements. |

|

XTRProf

Fully Modded

Pssst ! Got any spare capacitors ?

Posts: 5,689

|

Post by XTRProf on Dec 27, 2007 5:26:19 GMT

Hi XTRProf If you look at the archives you will see some of the improvements I made to the X-PSU V3. rockgrotto.proboards39.com/index.cgi?board=q&action=display&thread=11699841201. Take the bolt out the center of the transformer & replace it with a non ferrous type, like brass or stainless steel 2. take the steel cups that hold transformer in place & replace with copper. 3. I dampened the transformer directly using cork sheet cut to size, then sandwiched the copper together. I think you will find this a superior method to what you suggested. 4. I put an X2 class cap across the mains & neutral leads. I forget the value but it is in the discussion. That one you have to experiment with, as it is more down to the bugs in your power supply & musical taste. 5. I originally put a by-bee filter in mine but after all the other mods I made it sounded better without it. Don't think they don't work they do. If you try these suggestions then you can expect further improvements. Hi Aurun, Oh, you are from Indonesia. I'm from Singapore. Nice meeting you here. I'm very open minded and what you have suggested are indeed better ideas to improve the X-PSU V3 technically and sonically as copper and stainless steel are non magnetic. Also, your cork material is less messy then those car undercoat tar although the car undercoat will be superior in terms of damping those trans virbration compared to cork. As for mains filteration, I do have a cheapo Made In China filter upstream of the X-Dac V3. So those common and differential mode thingies will not affect the X-Dac V3. However, I do find with the filter the sound is not as dynamic and pratty. If I go mostly for vocal, jazz and classical, that will be more or less right for me with filter. Have you tried a balanced isolation trans of at least 2KVA before? The hot thingy now amongst Singaporean DIY circles. Your comments if have. Don't worry I'm very very open minded and please do speak your mind over that.  Cheers!  |

|

|

|

Post by aurum on Dec 27, 2007 6:45:26 GMT

I guess just below Indonesia would be that small country about the land size of America with 10% of the population. Trust me cork will be superior to tar in audio any day. To much damping can be as bad as not enough. its all about the balance. Try picking tar off if you don't like the changes its made  There are a few recipes using cork for mounting your gear as well. I have all my audio well isolated on bearings & brass feet. Using foam or rubber sucks to my ears. I have considered using a sheet of mu metal inside the housing for superior RF rejection as well. I am currently feeding the CD player & X-PSU with a 2500Watt mains filtration unit made by my friend Lucas from Black Art Audio.  When deciding to put in filters its all about taste, if you find one that improves things then keep it. The beauty about having a handbuilt unit, are things like local knowledge & tweakablility |

|

XTRProf

Fully Modded

Pssst ! Got any spare capacitors ?

Posts: 5,689

|

Post by XTRProf on Dec 27, 2007 12:34:04 GMT

Oh, you are same as Alex from the land of Downunder. Good.  Ya, you are correct. I wouldn't be able to remove the tar car undercoat if I don't like it. I really like your idea of mu metal for shielding. I reminded me of the magic bricks some years back when placed on top of the trans. On top of knowledge and tweakability, there is also the honour and pride of owning something which only you have when handmade. In other words, one of it's kind in this world. I'm sure everyone will treasure it better than when bought fully assembled. I'm now in my second phase of tweaking and that's the X-dac V3. Let's see what things come up. ;D |

|

XTRProf

Fully Modded

Pssst ! Got any spare capacitors ?

Posts: 5,689

|

Post by XTRProf on Dec 28, 2007 5:04:40 GMT

Hi Ian, Wow, how did you manage to cut such a neat round cooper plate out of a stock plate for the trans. This I really must find out.  |

|

|

|

Post by aurum on Dec 29, 2007 0:10:56 GMT

Take the round standard steel cups & scroll a line around them onto a sheet of copper, then use good quality serrated tin snips. A soft hammer will bring things back into shape.

Make the center of the hole & its done.

|

|

XTRProf

Fully Modded

Pssst ! Got any spare capacitors ?

Posts: 5,689

|

Post by XTRProf on Jan 2, 2008 4:51:02 GMT

Take the round standard steel cups & scroll a line around them onto a sheet of copper, then use good quality serrated tin snips. A soft hammer will bring things back into shape. Make the center of the hole & its done. Wow, you use a metal snip to cut it? That will really be hard work and must be with strong arms. Let's say 1mm to 1.5mm copper plate, oh, you are muscle dude, man! You must have trained with irons for the Olympics.  |

|

|

|

Post by aurum on Jan 5, 2008 11:34:33 GMT

Copper plate is as soft as hell, no muscle required. A 2 year old could cut it. Brass plate is an alternative, as it is even softer to cut.

Now machining a bar of copper on a lathe is tough.

|

|